Manufacturing and processing

Food manufacturing and food processing is the conversion of raw ingredients are turned into the final food product. Food manufacturing and processing can be done using many different methods. Below is a collection of articles related to food manufacturing and processing. To find out more about our food process and manufacturing services get in touch – support@campdenbri.co.uk.

Variability of air-fryer performance and its impact

In this video, Greg Hooper outlines the air fryer testing performed by his team, the various challenges uncovered, and how these impact considerations for ge...

Examining a key update to the ISO 22000 and FSSC 22000 standards

In this short video, Richard Leathers, Global Quality Lead, discusses a fresh update to the Prerequisite Programs (PRPs) that help and support the ISO 22000 ...

Cooking instruction services: Why you need them and how we can help

In this video, Greg Hooper discusses the science behind cooking instruction development, and why this is so crucial to ensuring instructions put on food pack...

Cooking (heating) instruction validation

The new BRCGS Global Standard Food Safety Issue 9 – Clause 5.2.4 relates to ensuring safe cooking (heating) instruction validation.

Heating characteristics of domestic air fryers – technical challenges affecting cooking instruction validation

In this white paper, we explore the implications of the variability in pre-heat time, temperature dial accuracy and cooking time.

Showcasing the benefits of induction heating

Discover how induction heating works, its applications and benefits, and experience it for yourself with our production trials.

Gap analysis: What is it? And when might you need it?

In this short video, Richard Leathers, Global Quality Lead, discusses consultancy gap analysis and why it is crucial to a food business.

Cooking instruction services: Why you should examine the scientific rigour offered by your service provider

We outline some key considerations to help you examine if your existing partner is delivering what you need.

Conducting a consultative review of a Campden BRI member company’s QMS

Discover the many streamlined benefits our client gained following our consultative review of their QMS.

Save time, money and transform your thermal processing with ThermaGen

Campden BRI are excited to announce the launch of ThermaGen, an online application offering predictive calculation capability for those working in thermal pr...

Helping food manufacturers manage the microbiological risk in low and intermediate moisture foods

Explore how we support food manufacturers in enhancing the management of microbiological risks in low and intermediate moisture foods.

Further strengthening our thermal processing service offerings

See how we have strengthened our thermal processing service with a wide range of support available around process optimisation and cycle development.

Insights from our Brewers’ Day event

Discover what we do to support our members in the brewing industry with a look at the highlights review piece from our recent Brewers’ Day event.

Exploring the pathogenic challenges and uncertainties with low/no alcohol beer

Find out about the latest issues and research we’ve been exploring in brewing microbiology, which we will also discuss in more detail at our Brewers’ Day event.

Key insights from our SafePlate 2024 event

Read how we support the thermal processing industry, offer guidance with topical presentations from experts and networking opportunities at our SafePlate event

Our research journey to date – supporting the food and drink industry for more than 100 years

Research activities of the ‘Campden Experimental Factory’ and its subsequent iterations, what we do for the food and drink industry now, and how our latest r...

Our new pasteurisation optimisation research

To demonstrate that yeast ascospores can be used as a pasteurisation bioindicator for the validation of flash pasteurisation for various alcoholic and alcoho...

The ultra-processed food challenge

UPF often describes the ingredients within a food or drink, not the necessarily the product itself. Nutritional research on UPFs has demonstrated some intere...

New ingredients, new processes: managing established risks

With the adoption of new ingredients and processing technologies, food business operators need to be aware of the associated food safety risks so that they c...

Microbiological safety of plant-based meat alternatives

Plant-based food production often involves ingredients and processes that wouldn’t normally appear in their meat-based counterparts. As such, producers of pl...

Highlights and insights from Millers’ Day 2024

We cover the detail of the presentations given by our in-house experts, on ultra-processed foods, developments in cereal testing methods, and food allergen c...

Safely achieving clean label products through thermal, non-thermal and emerging processing techniques

‘Clean label’ innovations require developers to strike the right balance between various considerations. The choice of processing also needs to be factored i...

Understanding and controlling the threat of Shiga toxin-producing E. coli

Looking at the difference between Shiga toxin-producing E. coli (STEC) and non- Shiga toxin-producing E. coli, and how to control these pathogens and prevent...

Controlling Shiga toxin-producing E. coli (STEC) – preventing contamination and recalls

Recalls of various prepacked, ready-to-eat sandwiches, wraps and salads have recently been announced due to possible contamination with E. coli. Is your busi...

How to ensure robust challenge testing in process validations

Key considerations for conducting process validations, including challenge testing. Plus, some specific examples of how we help ensure that worst case is val...

Optimising food allergen management – through risk management and risk communication

This white paper is structured into these four key sections and summarises some of the key insights and updates shared during our ‘Optimising food allergen m...

Decontamination of herbs and spices – process validation and challenge testing for both established and emerging technologies

Herbs and spices can harbour pathogens but their quality can be negatively impacted by established decontamination processes.

Preparing for 2024 – expected trends and challenges

What food and drink industry trends and threats are you preparing for as we head into the coming year? How will you and your business navigate the challenges...

Achieving sustainability and efficiency through new technologies

By adopting advanced technologies and best practices, manufacturers can improve the efficiency and sustainability of many different food and drink processing...

BRCGS Global Standard for Food Safety Issue 9: most common non-conformances

Our thoughts on the most common non-conformances raised since audits against Issue 9 began in February.

Asking our network about their food allergen cross-contact concerns

We asked our LinkedIn network for feedback on allergen cross-contact via a number of poll questions about their concerns in this area.

Q&A: investigating off flavours and taints

Our experts share their knowledge of off flavours and taints, and how they can support you in this area.

Leveraging sensory insights throughout the product lifecycle

Explore the benefits of applying sensory analysis to produce robust sensory data and make more informed commercial decisions, as well as the risks of not inc...

Research, partnerships and accessing funding

Craig Leadley, Technology Fellow covers UKRI funding channels, connecting businesses to funding bodies and resources, the exciting research for which we have...

Four sources of food allergen cross-contact from throughout the food chain

Allergen cross-contact can occur at every stage of the food chain, from ‘farm to fork’. Among the many sources of risk that food business operators must cons...

5 reasons to optimise the pasteurisation of your beer and low pH beverages

Greg Rachon, Brewing Microbiology Section Lead, explains the benefits to beverage manufacturers of optimising their pasteurisation processes.

Using our manufacturing best practice service to support your certification

Hear from Richard Leathers about two very different factories to which he has provided Manufacturing Best Practice support to help the teams gain new certifi...

Are you getting the ingredients you paid for?

For more on analysis and testing, including rapid turnaround for urgent testing, visit our service pages.

Attending the Institute of Food Science and Technology (IFST) Spring conference 2023

IFST’s Spring Conference was on ‘Taming the Perfect Storm’ and the interconnecting health, nutrition, food security and environmental challenges facing our i...

Process validations for non-thermal and new technologies – have you validated the worst case?

We have explored factors outside those commonly considered in process validations, and found significant and substantial effects on the log reductions achiev...

Understanding and maximising the shelf-life of drinks

Understanding the quality deterioration that can occur to shelf stable beverages can help developers design their product and its production process to facil...

5 reasons to review product shelf-Life

Clearly shelf-life needs to be established as part of new product development, but there are plenty of other reasons why shelf-life must be reviewed – here w...

How to build a convincing business case for your food or drink product optimisation strategy

How can you take your product optimisation strategy from concept to reality? Ultimately, you need backing from stakeholders. Here we provide four simple step...

5 ways to benefit from food processing improvement strategies

Food processing technologies improve the efficiency and safety of the processes used to transform raw materials into finished food and beverage products. By ...

Ingredient functionality: unlock power and control through detailed understanding

Knowing the purpose of each ingredient in your product, and what characteristics enable them to fulfil these, can help manufacturers to overcome challenges w...

3 ways to cost-optimise your food and drink products to protect profits

Cost optimisation is one of two critical components of product optimisation, focussing on maintaining the value and quality of a product while improving its ...

Minimise costs and maintain quality: 4 steps to successful reformulation

Now more than ever, your products must deliver superior value and quality at the lowest possible price. Regular cost optimisation — even for products that ar...

Strategies to maximise food and drink product revenue while maintaining quality

Do you want to stay ahead of your competitors by maximising the market potential and profitability of your products? To deliver unrealised potential from you...

So, you've optimised your product - but do your consumers agree?

Removing cost from your product can help to improve profitability, but you must also protect what your consumers value most. Conducting consumer research pre...

Could your process benefit from pulsed electric field technology?

Danny Bayliss, New Technology Lead and Alicja Staskiewicz, Process Technologist share how pulsed electric field (PEF) technology works and the many ways it c...

5 reasons to proactively optimise your food and drink products

As the global population continues to increase, so do the opportunities for food and drink manufacturers and suppliers.

What will 2023 bring for the food and drink industry?

What food and drink industry trends and threats are you preparing for as we head into the coming year? How will you and your business navigate the challenges...

Pet foods and the unknown risk to human health

Over the years, the pet food industry has suffered several foods scares resulting in adverse health effects to those owning pets and financial impacts. In th...

Reformulation can lead to cost savings and increased sustainability

This client came to us to reduce the fat content of their gluten-free bread. The team was able to achieve a fat reduction of over 30% while maintaining the s...

Webinar: Meat and poultry MIG - Spring2022

Your Member Interest Groups (MIGs) meetings were online this Spring. Thursday 10 March 2022

Webinar: Processing, operations and preservation MIG - Spring 2022

Your Member Interest Groups (MIGs) meetings were online this Spring. Wednesday 9 March 2022

Superchilling has positive impacts on food preservation and energy consumption

With over 10 year’s experience of helping the industry to superchill their products, we are the food and drink sector’s preferred choice to support with exte...

Webinar: Processing, operations and preservation MIG - Autumn 2021

Your Member Interest Groups (MIGs) meetings were online this Spring. Thursday 19 October 2021.

Cutting down on food waste while maintaining food safety

How can you cut down the food waste in your food business while ensuring food safety? Find out with these tips from our experts.

Webinar: Meat and poultry MIG - Autumn 2021

Your Member Interest Groups (MIGs) meetings were online this Autumn. Thursday 16 September 2021.

The digitisation of processing – what role does Industry 4.0 play?

What are the benefits of applying Indsutry 4.0? In this blog we use a recent case study to demonstrate how introducing Industry 4.0 to an SME bakery boosted ...

New guideline for heat preserved foods in progress

Do you use heat to preserve foods but lack up-to-date guidance? We’re currently revising guidelines to help the industry manage risk in this area with the be...

UK Salmonella outbreak - the chicken bites that bite back

You’ve likely heard of the UK’s large food poisoning issue associated with Salmonella enteritidis. It’s linked to certain retailer-sold breaded chicken produ...

5 things to consider before validating your thermal processes during COVID-19

It’s essential that your thermal processes are validated correctly. Find out from our expert what you need to consider before validating your thermal processes.

Remote auditing to help you manage risk during the COVID-19 pandemic

COVID-19 has created global issues that have dramatically impacted food business operators.

Technical challenges associated with reducing or replacing single use plastic packaging within the food and drink industry

This project will provide members with a better understanding of the UK’s recycling infrastructure for single use plastic packaging and exploring alternative...

Intelligenc dough mixing using AI

The subject of bread making was one we thought as ideal for applying AI to model the process

Pre-processing to improve natural nutrition and functionality of ingredients

This project will develop knowledge on nutrient bioaccessibility and bioavailability to optimise the nutritional value and technical function of the food pro...

Technologies for detection of foreign bodies and internal defects

New technologies will be reviewed, and practical trials of their capabilities will be conducted for foreign body and defect detection.

Better factory hygiene: microbial population dynamics in food factories

Investigating the microflora of factories making different product categories including the changes in microbial populations over the course of a year during...

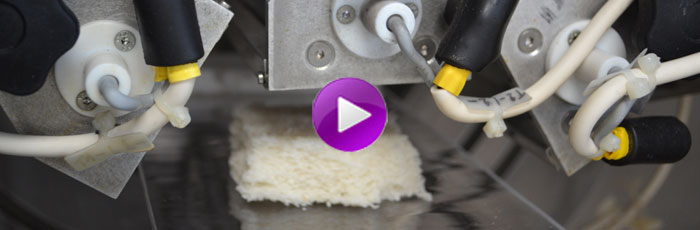

3D printing of food

3D printing is a rapidly growing technology that is already in widespread use for customised,

New technologies for food manufacturing

The focus for this project will be emerging technologies for improving quality and value and will conduct feasibility studies on commercially relevant emergi...

Environmental monitoring – are you complying with BRCGS Issue 6?

Manufacturers of food packaging materials are now required to implement a microbiological environmental monitoring program, where appropriate, based on risk.

3D printing of food

This project will explore the potential and limitations of 3D printing for the food industry.

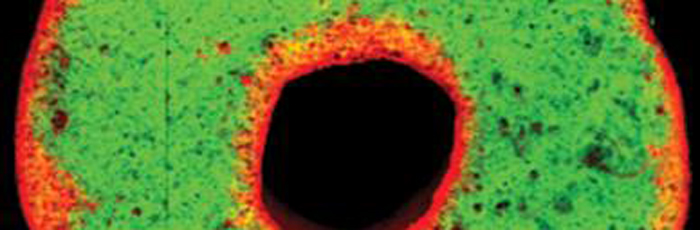

Inactivation of bacterial biofilms – new approaches

The aim of this project is to define the resistance of key spoilage organisms in their biofilm state.

Practical control of Listeria during food production

This project sets out to produce an up to date one-stop-shop guideline document on controlling Listeria during food production.

Chorleywood Bread Process – how it’s changed industry

If there is an iconic baking process that has come out of the British tradition, it would be the Chorleywood Bread Process (CBP) developed in 1961 by scienti...

Modelling and simulation of food processes

Simulations enable the effects of process conditions to be evaluated and optimised computationally prior to experimental validation

Are your cooking instructions correct?

Instruction validation relates to the need to ensure that cooking and heating instructions for consumers are tested rigorously, to ensure that food is safe t...

Thermal process validation - methods

David Whittaker covers the methods we use to build the evidence that allows us to determine whether a thermal process will deliver a safely processed product.

Thermal process validation - analysis and optimisation

David Whittaker covers how we interpret and use the results from a validation study to optimise a thermal process.

Repurposing waste for ingredients: reusing and recycling food materials

‘Getting more from less’ was a major ‘need’ articulated by our members when we asked them what they needed from science and technology. We’re all aware of th...

What are the benefits of continuous microwave processing?

Continuous microwave processing uses this mechanism to heat a product as it continually flows through a chamber.

Short-run canned food – ideal for intervention feeding trials

The University of Glasgow’s School of Medicine, Dentistry and Nursing wanted to run an intervention trial to assess the health impacts of ingredient changes ...

How to validate emerging technologies in food processing

Process validation is the collection and evaluation of data to establish that a process is capable of consistently delivering a safe product.

3D printing of food

Gael Delamare explains how a member funded research project will evaluate 3D printing.

Physics in food manufacturing

An initiative from the Institute of Physics (IOP) recognises the food industry as an important sector

The application of validation principles to continuous thermal and non-thermal processing

The beauty of continuous thermal processing is that it allows a large quantity of product to be processed in a short time.

New technologies for food and drink manufacturing

This webinar explains the feasibility studies that occurred up to June 2017, including UV-C and pulsed electric field processing. (Member ac...

Pulsed electric field - the potential in food processing

Pulsed electric field processing is a well known non-thermal food preservation technique, but did you know it can also be used to improve product quality and...

Five common process validation mistakes

Process validation is the collection and evaluation of data to establish that a process is capable of consistently delivering safe product.

On-line technologies for food process control

This presentation considers a member funded project for reviewing a range of online sensing technologies. The webinar discusses the developm...

Aseptic processing - process and hygiene

The aim of aseptic processing is to produce a sterile product through heat processing.

Checking processes work

Validation of processes is an essential part of the manufacturing of food and drink.

Ultra-violet light and decontamination

Emerging technologies specialist Danny Bayliss discusses ultraviolet (UV) light and its use for decontamination of surfaces in the food and ...

Validation of cleaning

Thorough cleaning is a crucial prerequisite to sound hygienic conditions in any food manufacturing environment.

On-line technologies for food process control

Martin Whitworth discusses the progress of our research project into online process control. (Martin Whitworth)

Mathematical Modelling - Get a slice of the action!

Have you ever considered using mathematical modelling to simulate your own process?

High protein drinks - formulation and processing

Nutrition specialist Fraser Courts discusses a new approach to assessing the stability of high protein drinks during thermal processing.

UV light tunnel

UV light treatment is a non–thermal, non–chemical technology to inactivate microorganisms.

Microbiological aspects and considerations of a range of process technologies

The development, evaluation, commissioning and validation of new process technologies has one common goal.

Preserving nutritional content

Julian South and James Luo discuss processing and preservation techniques that have a major role to play in optimising the nutritional content of ...

Technology innovation, development and validation

In a world which is constantly changing, manufacturers must adapt to stay ahead of competitors and continue to meet consumers' needs.

High pressure processing

High pressure can be used not just to pasteurise food products, but also to change their characteristics.

Training course helps Pukka Pies reduce pastry waste by 40%

With the help of our training in pastry technology, the Pukka Pies team were able to use their new knowledge to re-design their production processes and redu...

Dry decontamination techniques – What are the emerging options?

Wet decontamination techniques have been traditionally used to remove microorganisms from foods and surfaces.

Cold plasma

Although cold plasma is not yet established in the industry, it offers applications that could have significant benefits.

Improving oven efficiency for Spooner Industries to save up to £14,000 per oven on running costs

Our research into the flow of air in bakery ovens has helped in the development of a new oven system which is around 5% more efficient than that with a conve...

Flash pasteuriser

New Armfield HTST/UHT unit in our pilot plant means that we can flash pasteurise products prior to carbonating and filling.

Thermal process validation – always a hot topic

Verification is a key requirement for safe food production and confirms that a food safety system based around HACCP is working effectively.

Surrogates for process validation

In my blog this time last year, I mentioned in passing the use of surrogate microorganisms in process validation regimes.

Thermal – seven things you need to know about thermal process compliance....

Thermal processing is at the very centre of food preservation and is one of the most well-known and practiced areas of food manufacturing.

Food reheating instructions

The selection of re-heating instructions using appropriate appliances can have a huge impact on the nutritional content and organoleptic quality of the food.

Pasteurisation of dried ingredients

The pasteurisation of dry ingredients requires specialised conditions.

The microbiology of process validation

The evaluation of the effectiveness of any food preservation process to reduce the target microbiological population is complicated.

Thermal processing validation

Joy Gaze and Martin George explain how microbial surrogates are regularly used in processing trials to determine the lethality of a process.

Power ultrasound

A versatile technique which has many applications in processing and is effective in microbial inactivation.

Pulsed light processing

This video demonstrates the use of pulsed light for the surface decontamination of food.

Cold plasma inactivation of food microorganisms

Danny Bayliss talks about how problem microorganisms can be inactivated by exposure to cold plasmas, and how this could deliver new cleaning ...

Innovative processing – if it's new, we're interested

With the drive still on for 'clean label' products and products that have fresh tasting characteristics with a good shelf life, the interest in 'new technolo...

How to pasteurise dry ingredients

Technologist Craig Leadley explains how to pasteurise dry ingredients, and new equipment at Campden BRI that could help companies with their ...

Developing cooking (heating) food product instructions for microwave and conventional ovens

Selecting the correct packaging and providing good heating or reheating instructions is as important to the quality and safety of heated product as is the ef...

Air flow management

Martin George of our Food Manufacturing Technologies Department talks about modelling air flow, factors that affect it, and how it can contribute ...

Salmonella management in low water activity food products

How Salmonella survives in environments associated with production of low water activity products.

Positron emission particle tracking

Martin George talks about positron emission particle tracking (PEPT) and how this can be used to assess the effectiveness of mixing operations.

Time-temperature integrators

Martin George explains what time–temperature integrators are and how they can help in the validation of thermal processes for a range of hea...

Emerging technologies

Craig Leadley talks about emerging technologies such as high pressure processing, ohmic heating and power ultrasound, and how these can help with ...

Pulsed light technology for surface decontamination

In this interview, reproduced courtesy of FoodProductionDaily, Campden BRI´s Craig Leadley talks about some of our work on pulsed light tech...

Research collaboration in seafood processing

Helping address the technical needs of the seafood sector.