Modelling and simulation of food processes

By Andrew Bosman - 28 August 2019

Mathematical modelling and simulation are increasingly used throughout the process industries - including food manufacturing - to study, improve, and develop products and processes. But what are the benefits? We’ve broken down the potential applications to help you find out.

Simulations enable the effects of process conditions to be evaluated and optimised computationally prior to experimental validation, saving on costly process trials. Advances in computer technology and powerful simulation software, now available at Campden BRI, enable well-established physical and food engineering models to be applied to complex real-world problems.

Simulations have multiple benefits when compared to traditional experimental studies. Firstly, in comparison with measurements at discrete positions in a system, simulations provide comprehensive predictions of the properties of a system at all positions and times. For example, for a cooking application, temperature probes provide information only at a small number of fixed, and practically accessible points, but simulations enable the complete temperature distribution and time-temperature profile to be evaluated, providing confidence in whether safe conditions will be achieved throughout a product.

Another powerful advantage of simulations is their capability for relatively high throughput experimentation. Once a model is defined, it is possible to simulate the effect of changing parameters (such as increasing cooking temperature or modifying product rheology) much more easily than it would be to run a physical experiment. This allows a large number of “what if” experiments to be rapidly run on a computer and at relatively low cost compared to laboratory or pilot (physical) experiments.

Campden BRI has the capability to model physical processes using combinations of:

- flow of liquids and gases

- heat transfer

- mass transfer

- chemical reactions, and

- structural mechanics

Example applications

Optimising mixing performance

A classic modelling application is the use of computational fluid dynamics (CFD) to simulate motion of liquids and gases. This has widespread applications in food manufacture – for liquid food products, and for air in factory environments, ovens or chillers. Examples for mixing range from product flow through static mixers to the design of impellers in stirred vessels. Because the fluid dynamics are resolved at all points in space, simulations allow prediction of parameters that would not by possible to measure experimentally: a key example is the local shear stress in flowing liquids.

Nearly all fluid food products are non-Newtonian, meaning that their apparent viscosity depends upon the local shear rate, strongly affecting their behaviour through process equipment. By simulating this behaviour, it is possible to deliver a much more detailed understanding of what is happening during mixing processes, therefore enabling improvements that can reduce processing time, reduce energy costs, and improve product quality.

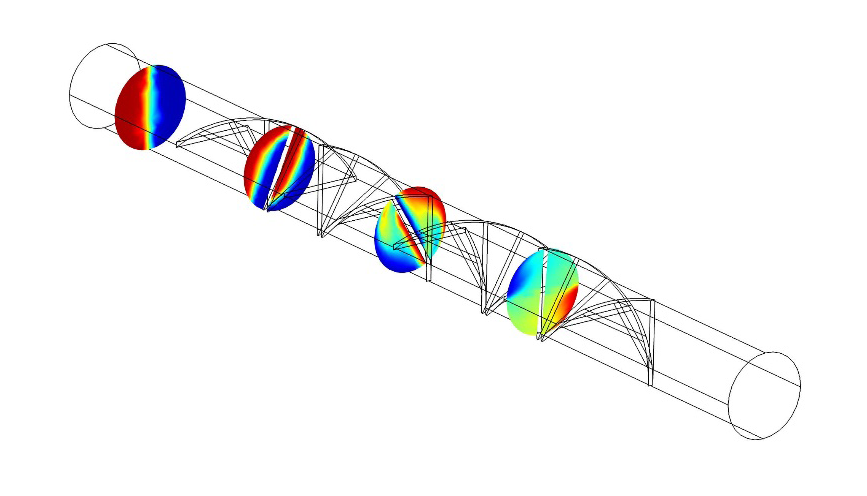

Figure 1: This image shows predictions of a chemical’s concentration in a static mixer after 20 seconds of mixing. The more uniform the colour the more uniform the concentrations.

Heat processing

As already mentioned, it is often difficult to know the temperature of a product while it is being cooked. Even where access for probes is possible, they are still only point measurements; how do you know if your probe is really at the coolest part of the product?

This is another key area where modelling and simulation are powerful tools. By simulating the temperature at every point in space and time within a cooking process, the lethality and quality properties of the food being cooked can be known in detail. This is important information when looking to optimise a cooking process, enabling cooking times and temperatures to be optimised to ensure lethality standards are met whilst minimising any cost and quality implications of overcooking.

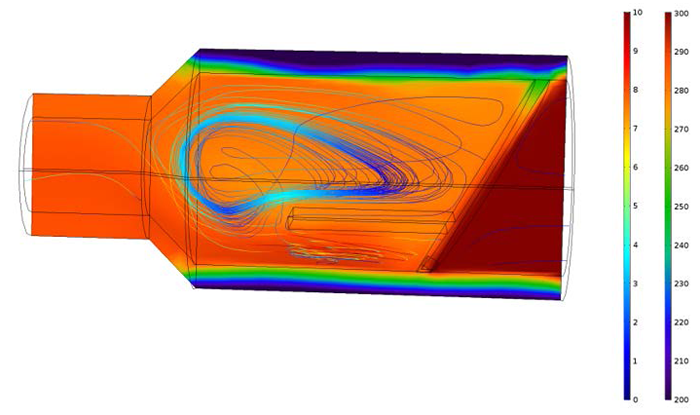

Figure 2: Simulation of heat transfer and airflow in a novel oven design. The streamlines show the air velocity and the image’s background colour shows the temperature predictions. Image measured in °C

Hygienic design

Modelling and simulation are also useful tools for process design. CFD has been used to study the efficacy of clean in place (CIP) systems, highlighting areas of process equipment where local fluid velocities are low, and therefore cleaning is difficult. Again, the high throughput nature of simulations is hugely valuable for design, where the effect of changing parameters such as cleaning fluid pumping velocities or pipe design can be quickly and cheaply assessed to maximise cleaning performance.

In general, modelling and simulation are powerful and versatile tools that can be used to help deliver deeper understanding of processes and products to reduce processing time, reduce cost and improve product quality. If you would like to know more about how Campden BRI can use these tools to help you, please get in touch.

Contact: Support Team

+44(0)1386 842291

support@campdenbri.co.uk