Why carry out microbiological testing on food and drink products?

11 February 2025 | Tina Shilham, Section Lead - Microbiology Analytical Services

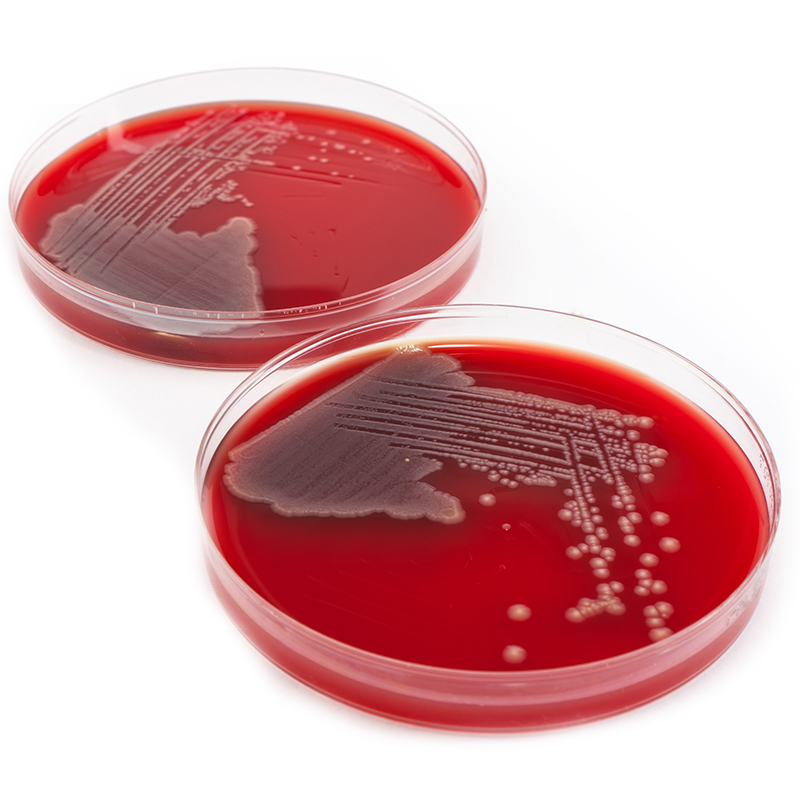

End-product testing remains a vital part of any food manufacturing control strategy. For products in which microorganisms can survive and grow, routine microbiological analysis is important to confirm that manufacturing control mechanisms are effective. It is also necessary for checking raw material quality (e.g. to confirm that they are within specification), or for investigating customer complaints.

For the food, drink and allied industries, we offer a comprehensive range of testing for raw materials, semi-finished products, finished products, environmental monitoring samples and more.

This blog covers reasons to test, as well as some typical examples and how we can help.

Microbiology: Protect your business and your customers

Protect your customers and your brand from risk with Campden BRI’s unique wrap around testing and advisory microbiology solutions.

Why test for micro?

While no end-product sampling scheme alone can provide full confidence in food safety, testing is an important part of any food safety management system – to show that the risk management systems are working and to show due diligence. Plus, it can prevent considerable costs to a business.

Whether adhering to customer / retailer requirements, demonstrating compliance to specifications, ensuring due diligence, conducting positive release testing, validating a new product or process, shelf-life testing, or troubleshooting / investigating an issue, there are plenty of reasons to conduct microbiological testing on your products.

Some key areas of testing include routine testing, commercial sterility testing, spoilage testing and troubleshooting.

Routine testing

Routine testing may be for compliance to internal, retailer and/or customer specifications, for monitoring, to confirm the effectiveness of risk management systems, for due diligence and/or for positive release of batches of product.

Determining what to test for (where this is not already set out) comes down to which foods are prone to which pathogens. This will depend on how the food is grown, harvested, handled, processed and packaged. It will also depend on the type of product (e.g. ready-to-cook versus ready-to-eat) and will change based on the composition / formulation of the product.

As well as deciding what to test for, the number of samples needed from a batch to be able to show that the risk level is acceptable will also need to be determined.

Commercial sterility testing

We can test for commercial sterility in both high acid (low pH) and low acid (high pH) products.

After two weeks of incubation, which we do in-house, a full suite of testing (which takes 1 further week) is conducted. The method, which we developed and is well recognised in the industry, is carried out to determine whether any viable microorganisms are present in the sample.

This testing can be applied to validation trials, as well as to routine positive release.

Spoilage testing

This testing is to determine the presence of spoilage microorganisms and, in particular, to investigate spoilt product.

Using the same methods as for testing commercial sterility (though without the incubation period), we can investigate what organisms are causing spoilage based on those that grow in this testing.

Applications include investigating spoilage issues – either known or suspected – such as that discovered in your own warehouse or from a customer or consumer complaint.

Troubleshooting

Whether investigating an issue picked up with product within your facility, an unexpected result from routine microbiological testing, products not lasting their full shelf-life, or a consumer or costumer complaint, microbiological testing can help you get the answers that you need.

When it comes to investigating spoilage for example, such as blown cans of drink, our packaging, microbiology and thermal processing experts can all help you to investigate the cause, so that you can fully understand and resolve the issue and prevent reoccurrence.

Specific microorganisms can be associated with specific food categories and origins, so understanding which organisms are present can provide an indication of what’s leading to a contamination issue. For investigating contamination by identifying the specific microorganism present in a sample, see our blog on microbial identification.

How we can help

We can support you in determining routine testing plans, including helping you know what to test for and how many samples. We can help you to appreciate the differences between standards, guidelines and specifications, and can guide you on current legal requirements.

We also provide support with troubleshooting and investigating insterility and spoilage issues – both in determining appropriate tests and interpreting results.

We can start testing on the day of sample receipt (if notification is given), have no hidden charges, and can offer expert support with results interpretation.

How can we help you?

If you’d like to find out more about microbiological testing, contact our support team to find out how we can help.

Find out more

Learn more about the microbiological analysis and testing services that we offer.