Further strengthening our thermal processing service offerings

27 February 2025 | Brendan Charles, Processing Project Specialist

The Process Innovation team at Campden BRI has further strengthened its thermal processing service offering. With investment in new equipment and the development of specialist expertise there is now a wide range of support available around process optimisation and cycle development, building on our well-established validation capabilities.

How can these thermal processing services help you?

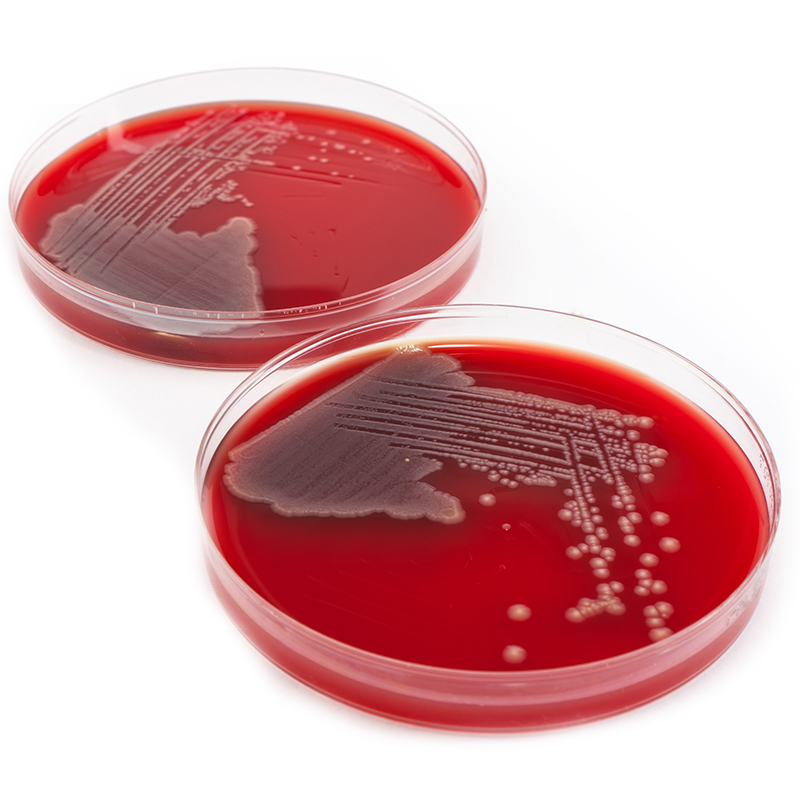

A thermal process is designed to eliminate or reduce microorganisms, those related to product stability and importantly, pathogens, through organisms considered harmful to public health.

Microbiology: Protect your business and your customers

Protect your customers and your brand from risk with Campden BRI’s unique wrap around testing and advisory microbiology solutions.

Given the complexity of many thermal processed products, and the food production lines where they are being used, the job of keeping microbiological risks consistently low remains a significant ongoing challenge for food manufacturers.

Part of this challenge is ensuring the equipment is performing optimally, through the development of a suitable programmed cycle, or by the control of product related critical factors.

A sub-optimal thermal process will have many implications:

- It is more challenging to control the microbiological food safety risk

- Unnecessary energy usage

- Operational inefficiencies (for example if cycle times are longer than they need to be)

- Elevated rates of customer complaints

- Inconsistent product quality

Any food manufacturers interested in reviewing their thermal processing, from either the perspective of food safety or quality can call on the expertise of our thermal processing and microbiology specialists to provide a consultative review of their thermal processes.

How we can optimise your process

Whichever thermal processing technique and supporting equipment you are using, our experts can work with you to optimise your process, such as:

- Improving temperature distribution and control on thermal process equipment

- Reducing process time through greater understanding of critical factors

- Reducing process times through improved performance of critical factors

- Providing insights to reduce rejects and quality complaints, for example by optimising process pressure using specialised equipment such as deflection loggers

- Reduction of energy usage due to excessive venting or use of air to control your equipment’s programming

- Use of predictive modelling software to explore and understand different options that need to be investigated

- Challenging the target process by reviewing and/or testing the heat resistance of specific microorganisms, utilising the capabilities of our fully equipped microbiology department.

Food safety is always paramount, but we find there are often huge optimisation gains to be made through some of the above activities. This could be through improving the temperature control and distribution of the machine, or by improved control of a critical factor, activities that can provide real value-add in terms of potential cost efficiency savings for clients.

Further ways we can support you with thermal processing

Besides helping you with process optimisation, our experts can provide much wider support in the area of thermal processing.

For over 100 years we have been a leader in food and drink thermal processing. Our team holds extensive experience in supporting processors within the UK and around the world, regularly working with some of the world’s biggest food and drinks companies.

Our thermal processing team at Campden BRI can support you in three key ways.

Thermal process validation

To ensure thermal processes are effective and repeatable, and consistently produce safe products, our experienced technologists can provide a range of methods to undertake third-party thermal process validation work at manufacturers’ sites. Using specialist equipment, we follow robust protocols that ensure we can provide accurate results and clear conclusions.

Processing consultancy

As a thermal process authority, we have the expertise to support manufacturers with third-party process reviews – for example, FDA process filling for the US market and other consultancy services. Most of this work can be completed remotely to confirm that existing processing is sufficient or to explore process optimisation opportunities.

Thermal process training

Our thermal processing team runs a variety of scheduled thermal processing training courses which includes both generalised or sector specific, online or face-to-face sessions. We can also offer tailored training courses designed specifically for your organisation, whether you are a manufacturer, retailer or an accreditation body.

For more information about these services and the wider support that we offer for thermal processing, please visit our thermal processing services page.

How can we help you?

Have you got an urgent question on thermal processing that you need answering?

Want to enhance your thermal processing skills?

Take a look at the wide-ranging courses we offer in the field of thermal processing, both online and face to face.