Our research journey to date – supporting the food and drink industry for more than 100 years

21 October 2024 | Craig Leadley, Technology Fellow

We have a rich history of serving the food and drink industry over the past century. As you would expect, our research journey tracks the evolution of the food and drink industry itself (from traditional preservation technologies through to the current period of vast consumer choice and demand for products that are healthy, affordable, sustainable and highly targeted to specific consumer groups).

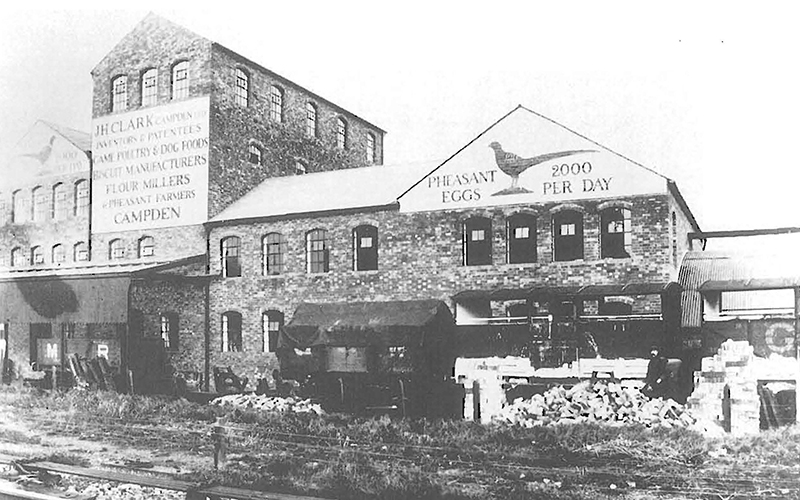

Founded in 1919 as the ‘Campden Experimental Factory’, and administered by the “Fruit and Vegetable Preserving and Drying Committee” of the UK’s former Ministry of Agriculture and Fisheries, Campden BRI was initially focused on understanding the fundamental principles of thermal processing and on helping to establish the emerging canning industry in the UK.

Of the wide reaching research activities over a long time, including predecessor companies, we give here just a few examples of some of these research activities of the ‘Campden Experimental Factory’ and its subsequent iterations, and how they reflect changes in the food industry over the past 100 years.

This blog also covers what we do for the industry now, and how our latest research programme aims to address the current and future needs of the food and drink industry.

The ‘Campden Experimental Factory’

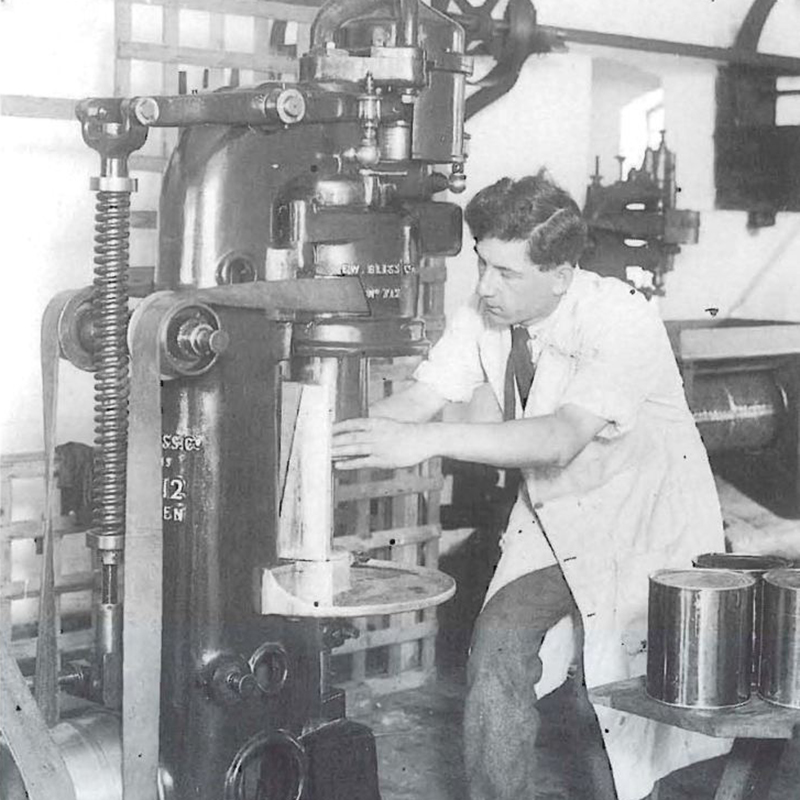

From 1919 through to the 1940s, we conducted extensive research in thermal processing fundamentals, with particular focus on heat treatments and freezing.

From the 1920s until 1952, we were an outstation of The University of Bristol, becoming established as a ‘research association’ in the 1950s.

By 1965, almost all of the canned fruit and vegetable producers in the UK were clients.

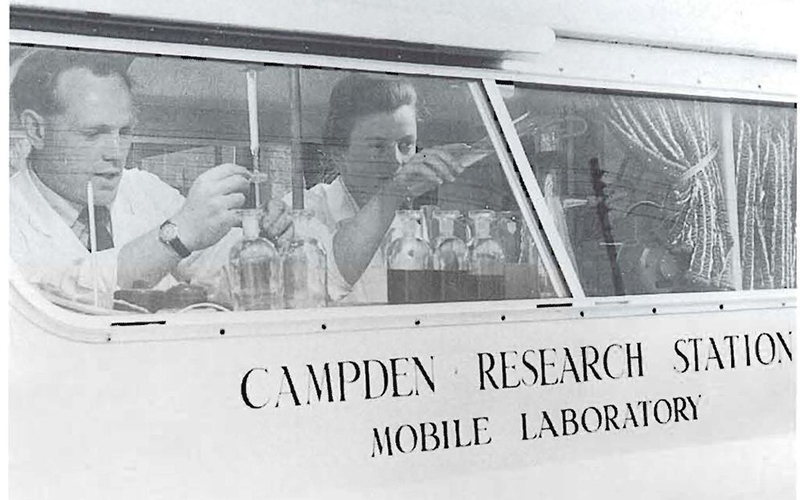

Thermal processing research in the 1960s and 70s

This period saw the continuation of trial work to optimise canning and freezing, alongside exploring new thermal processing approaches and monitoring techniques.

This included projects on sterilising foods in flexible pouches (1969-1978) and aseptic processing (1976-1979), as well as introducing aseptic processing capabilities to our pilot plant.

There were projects to create “computer programmes for process calculations” and implement new modelling techniques – for example, a heat transfer simulation connected to a retort for real-time calculations of process lethality (1975).

1980s and 90s – hygiene, HACCP and more on thermal processing and computer programmes

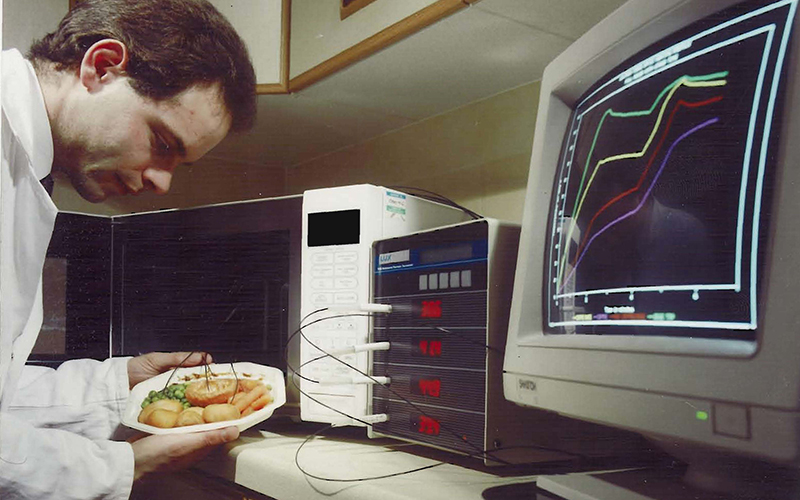

In the 1980s, we conducted research on early microwave processing technologies and ohmic heating, as well as energy monitoring and optimisation in the canning industry. As part of the growing use of computing in process management, we formed the ‘Campden computer control club’ during this same period.

We carried out a lot of work in relation to all elements of factory hygiene, particularly in relation to the emerging chilled food sector of the time (1980s / early 90s). Much of our hygiene work conducted at the time remains the basis of many current practices in the sector. We became a founder member of the European Hygienic Engineering & Design Group (EHEDG) and established an auditing standard that evolved to be the first British Retail Consortium Food Safety Standard Issue 1.

Plus, we published the world’s first industry guidance on the application of HACCP to food manufacturing in 1987.

A 1995 merger with the Flour Milling and Baking Research Association extended our services and expertise into the cereals, milling and baking sector. Plus, in 1998, our merge with Campden BRI Hungary (1998) broadened the activities and geography of the business.

From the 2000s to present

In the 2000s, we refined new techniques to measure process lethality, started work in surface decontamination techniques, and undertook projects on validating the safety and quality of flowing liquids and clean filling operations.

In relation to salmonella survival in dried products, research projects were initiated with respect to salmonella heat resistance in low water activity products (2003) and best practice for cleaning in dry food factories (2004). This was followed by work on decontamination protocols for pathogens in produce (2005).

Projects started to be commissioned around various food contaminants, such as allergens, acrylamide and endocrine disrupters (2003/2004). Plus, there was growing interest in new packaging techniques and research was conducted on active and intelligent packaging systems.

From around 2007, diet and health becomes a noticeable theme in our research.

From around 2007, diet and health becomes a noticeable theme in our research – with projects around ‘clean label’ starches, natural antimicrobials, fat replacement, sugar replacement, vegan product development and plant-based ingredients (2007 to date).

In 2008, a merging with Brewing Research International (BRI) extended the scope of our services into the fermented and alcoholic product sector.

From 2017, alternative proteins start to feature in our research. For example, projects related to ancient grains and the potential for insects as ingredients. More recently, we have been involved in a project on cultivating meat for space missions.

What we do for the industry now

As ever, we continue to evolve and adapt to anticipate and meet current and future industry needs, in order to provide unrivalled technical expertise and support for our members and clients.

We have over 100 years of expertise and are well-equipped to provide comprehensive support to food and drink businesses. Our wide range of services and products are all underpinned by investment in meaningful research and science. We are not just about providing results, but empowering members and clients with the understanding too.

Our research today

Today, our research programme is focused around 5 themes that reflect the needs identified through consultation with the food and drink industry. Food safety (1) is the core research theme at the heart of what we do. Our diet and health, digitalisation and sustainability themes (2, 3, 4) address industry needs – whilst always focusing on ensuring affordability (5).

Our commitment to collaboration with universities and other research institutions remains as strong as ever, as evidenced by our role in the Food Consortium Collaborative Training Partnership to support the next generation of food industry scientists. We are involved in several Innovate UK-funded projects that all started in 2023, where topics include the scale-up challenges for cultivated meat, novel decontamination methods for low water activity products and the development of novel ingredients.

Unrivalled support for our members

Our members are a global community that now includes over 4000 member companies in the food, drink and allied industries – from across more than 90 countries. Our members receive unrivalled technical expertise and support, and member benefits include:

- Expert support whenever you need it

- Peace of mind

- Saving money and time

- Gaining knowledge and staying up to date

- Connecting with experts and network with peers

- Getting ahead

- The opportunity to get involved, collaborate and influence

- And more – visit our membership page for the full list of what’s in it for you and your business.

Visit our research pages for more on our research programme and current projects. To further explore membership, get in touch with our Membership Team.

Research programme and projects

Check out our research pages for more on our research programme and current projects

Are you a Campden BRI member?

- If not, you’re missing out. Find out more about how you can benefit from our membership offering.

This blog builds on a previous article that appeared in Food Science & Technology Magazine