Helping food manufacturers manage the microbiological risk in low and intermediate moisture foods

14 March 2025 | Rob Limburn, Section Lead and Deputy Head of Microbiology

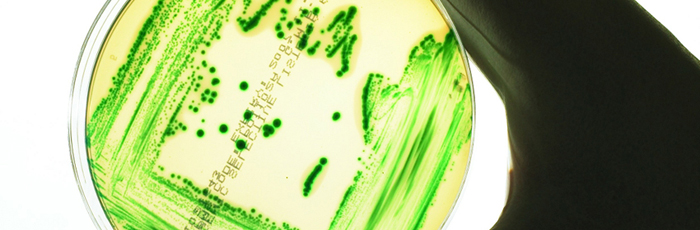

When it comes to foods, some food types are more susceptible to microbial contamination than others. For example, while meat, poultry, and seafood are particularly vulnerable to E. coli, Salmonella, and Listeria contamination, dairy products can become contaminated with pathogens such as Listeria, E. coli, Salmonella, Bacillus cereus, pathogenic clostridia and Campylobacter.

However, in comparison to these high-profile examples, awareness of the risks posed by other food types such as low and intermediate moisture foods is less high. Yet, according to the Journal of Food Protection they should be, as low moisture foods (LMFs) in particular are being increasingly associated with microbiological outbreaks and recalled as a result. In some cases, the problems with LMFs has been further exacerbated by the fact that nearly a fifth of today’s consumers don’t always correctly follow on-pack cooking instructions .

The complexities surrounding low and intermediate moisture foods

Yet, the issues surrounding what can increase the microbiological risks in LMFs are far more complex, and there is a lot more to consider before a food even gets to its final product and cooking stages.

...you need to think about that food product’s intrinsic properties such as its water, fat, carbohydrate content and more, as these can either contribute towards the growth of microbiological organisms...

Consider for a moment a finished baked product, which at this stage is likely to be low moisture (although not always). That same product during its earlier stages of production, is quite likely to have had more of a pure batter or a dough-based consistency, and a higher moisture content as a result.

At this point you need to think about that food product’s intrinsic properties such as its water, fat, carbohydrate content and more, as these can either contribute towards the growth of microbiological organisms or their resistance to heating.

Consequently, no matter whether you are dealing with low or intermediate moisture foods, or what stage of production you are involved with some level of microbiological risk will exist. So, if you are to minimise the safety risks to the consumer and the threat of a potentially costly product recall, it is crucial to obtain the right solutions, techniques and expertise to mitigate your microbiological risks.

Helping food manufacturers better manage and mitigate microbiological risks

In light of these issues, we are already supporting many clients with similar challenges, and our work is helping them to more safely determine what their food cooking instructions should be, as well as informing many of their industrial processes.

Microbiology: Protect your business and your customers

Protect your customers and your brand from risk with Campden BRI’s unique wrap around testing and advisory microbiology solutions.

Some of the key ways in which we can help manufacturers of low and intermediate moisture foods better manage and mitigate their microbiological risks includes:

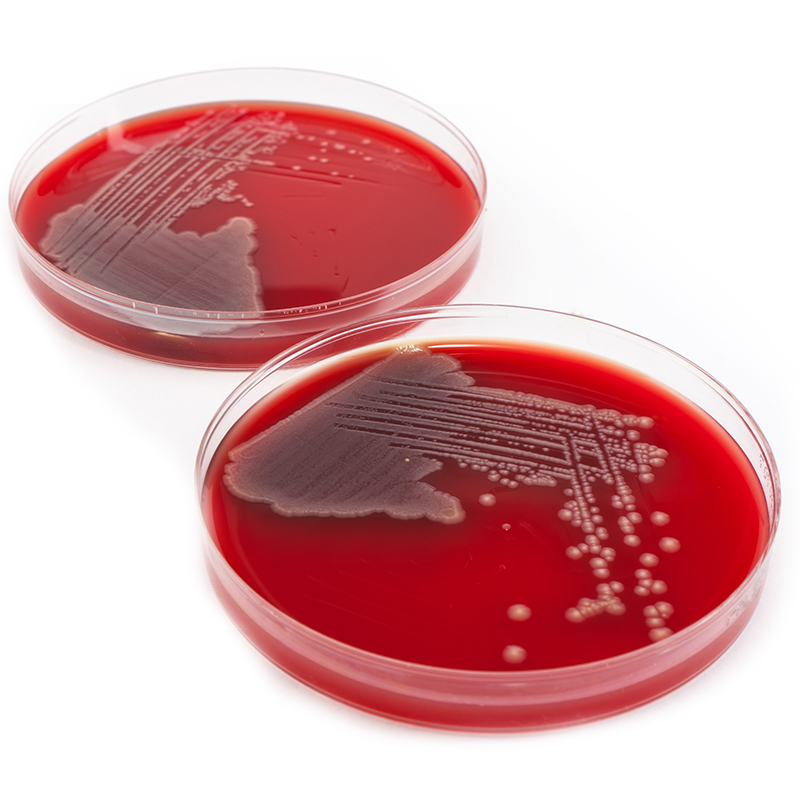

- Helping to validate their processes for the safe removal of microorganisms

- Microbiological challenge testing

- Advising them on the best technique to ensure their thermal processes are effective, repeatable and consistently produce safe products

In terms of techniques, if we take the example of some consumers undercooking their food and subsequently putting themselves at greater risk of microbial contamination, to mitigate this risk we would recommend manufacturers putting these food products through the pasteurisation process before making them commercially available. And the best technique for this is thermal process optimisation.

Maintaining safety and improving product quality with thermal process optimisation

When it comes to food preservation thermal processing is one of the most well-known and practiced areas of food manufacturing. It also has a crucial role in ensuring that foods are safe from microbiological contamination while ensuring they remain high in their nutritional and sensory attributes.

Yet, while food safety should and always will be paramount, the competitive pressures on food producers remains, which means that all their processes including thermal ones need to be carried out as efficiently as possible. This is where the benefits of optimising thermal processes come to the fore.

Reasons to optimise your processes and how we can help

During the many project trials our experts carry out to validate the thermal processes of our clients, we often find from their data a degree of over-processing – namely additional heating of the product which is not necessary for food safety. In such a scenario, manufacturers are missing out on some key benefits of optimising their thermal processes including:

- Greater energy savings with a process that requires less heating

- Higher throughput: shorter cook times leading to overall efficiencies in production

- Improved product quality and sensory perception

- Greater retention of the product’s nutritional attributes, as some vitamins such as A, B1 and C can be broken down with heat

In terms of supporting our clients in this area and to ensure their thermal processes are effective and repeatable, and consistently produce safe products, our experienced technologists can provide a range of methods to undertake third-party thermal process validation work at manufacturers’ sites. By employing specialist equipment, we also follow robust protocols to ensure we can provide accurate results and clear conclusions.

For more information about how we can provide you with microbiological and thermal processing support highlighted in this piece, please visit our respective microbiology and thermal processing services pages.

About Rob Limburn

Rob has worked in Microbiology here within both Methods Research and Industrial Process Microbiology. He has been working in the food industry since 2004 and also has experience in allergens testing and authenticity testing.

A trusted partner for your food microbiology needs

Guarantee food safety, save money and time with our trusted expertise for your food microbiology and related solution and support needs.

How can we help you?

If you would like to know more about how we could optimise your thermal processes, contact our support team to find out how we can help.