Pet foods and the unknown risk to human health

21 April 2022 | Roy Betts, Scientific Affairs Directorate

Did you know that if pathogenic bacteria or parasites are present in dog and cat food products, they can pose health dangers to both pets and their owners.

Over the years, the pet food industry has suffered several foods scares resulting in adverse health effects to those owning pets and financial impacts. In the past 3 months alone, there have been several UK Food Standards Agency (FSA) food alerts and one Department for the Environment, Food and Rural Affairs (Defra) import ban relating to pet foods.

Recalls are triggered for a variety of reasons ranging from contamination with a pathogen or foreign materials to the inclusion of potential allergens or adulterants. As well as being detrimental to a pet food company’s reputation and being extremely costly, food contaminated with human pathogens, such as Salmonella, Escherichia coli or Campylobacter, not only presents a risk to pets but also to anyone in direct contact with them.

In this fast-growing and rapidly changing industry, how important are hygienic and sanitary practices when manufacturing pet food?

Why is there a risk to people?

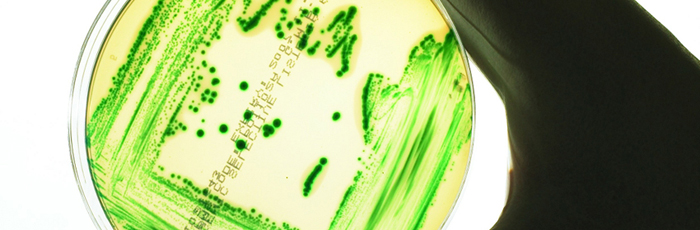

Bacterial contamination in pet food is a genuine issue for canned pet food, fresh, kibble, raw and treats. Like contamination in human food, contaminated pet food can contain various types of bacteria, some of these can seriously affect the health of pets, but the danger is not only restricted to animals.

Roy Betts, fellow at Campden BRI and expert in microbiology explains:

People can be infected when they touch the food during pet feeding. If they do not use good hygiene measures, they could transfer the bacteria from the contaminated food to their own mouth. It is also possible that contamination could be transferred to utensils or kitchen surfaces, spreading the organisms more widely and increasing the risks to others.

He added:

Pets can also spread the bacteria from their mouths, saliva, fur, and faeces, even before showing signs of illness.

Given that some bacteria can cause serious infections in young children, the frail or elderly, and those with weakened immune systems, this is indeed a compelling reason for concern.

Raw food, under the microscope

A growing trend has seen pet owners plump for products such as raw meat, bones and organs which can be bought frozen and then thawed before being fed to dogs and cats. The concerns over the increasing use of raw pet foods have resulted in two FSA Strategic Advisory Committees discussing the subject over the last 5 years. Roy Betts noted that any pathogenic bacteria that are present only die when cooked at sufficiently high temperatures using validated heat processes. A challenge in dry pet foods are pathogens that may survive heat processes. Most bacteria including common pathogens like Salmonella, become much more heat resistant when in dry conditions and require significant heat processes to destroy them.

Problems in pet food manufacturing facilities

Roy Betts indicated that the key issues of critical importance in manufacturing areas are:

- Potential for cross-contamination of raw and finished products

- Inadequate or improperly implemented cleaning and sanitising programs

- Poor equipment design

- Product residues build up on processing equipment

- Air flows enhancing risks of cross contamination in the pet food manufacturing facility

- Water-related issues

Roy Betts continued:

With trends such as raw meat-based diets taking centre stage, focus on raw material standards, production hygiene, and good manufacturing practices is paramount. We should consider that pet foods need to be produced to the same exacting standards as any foods destined for human consumption.

Reducing contamination and cross-contamination

By confronting bacteria at its earliest stage and employing multiple steps and methods to ensure product integrity, the food safety risk of pathogens can be reduced. At Campden BRI, we have a wealth of expertise in food safety management for both the human and pet food industries. Over the years, we have helped manufacturers control and reduced pathogenic contamination in food processing factories, and consequently minimised the risk of recalls.

Our experts offer state-of-the-art services in detecting and controlling pathogens and can support you with:

- Process validation services for pet food/animal feed manufacturers to give certainty that processes will eliminate pathogens.

- Advice on hygienic production measures such as high-pressure processing

- Microbiology testing services for all major foodborne pathogens

Get In Touch

Contact our experts to discuss how we can help you reduce the risks of contamination and safeguard the quality of your manufactured pet products.

Interested in learning more about our pet food and animal feed expertise:

- Read our R&D on Heat resistance determination of Salmonella in low Aw foods

- We are running a Campden-funded research project, “Validating the inactivation of Salmonella in poultry feed”, which will provide a validated challenge test protocol and guidance document, as per industry requirements, for poultry feed thermal processes. Watch the Microbiology Member Interest Group video or contact Rob Limburn, the project leader, rob.limburn@campdenbri.co.uk for further details.

How can we help you?

If you’d like to find out more about the risks of contamination and safeguarding the quality of your manufactured pet products, contact our support team to find out how we can help.

Are you a Campden BRI member who attends the MIG meetings?

- If not, you’re missing out on a whole host of exclusive benefits such as learning from industry-leading experts and networking with peers to overcome your challenges.