Microbiology process hall

Joy Gaze, Dupty Head of Microbiology

Joy Gaze explains how our microbiology process hall allows us to incorporate pathogens into studies to mimic an industrial environment and evaluate how effectively processes reduce and eliminate contamination.

You may also be interested in

Transcript

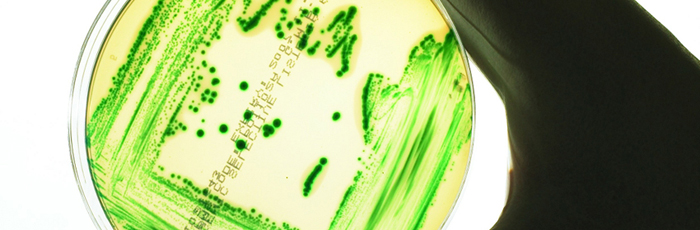

The microbiology process hall is an area where manufacturing equipment can be used with the inclusion of microorganisms. We're assessing the suitability of equipment to achieve certain things and by incorporating the organisms into the challenge tests that we're doing.

The microbiology process hall is different to a conventional pilot plant in literally the microorganisms. You can incorporate a whole range of microorganisms that are relevant to that particular product that you're interested in, so they can be pathogenic as well as yeasts, moulds, bacteria, the whole range. So, in that respect we can assess how lethal the processing step is or we can actually incorporate the organisms in a different way. If, say for example, it's a troubleshooting exercise where organisms are there unexpectedly we can simulate that and find out the reason why they're surviving.

The sorts of companies that could benefit from using the hall I think is very wide-ranging, it's new producers that are starting to set up business, it could be somebody that's doing development work on a new product or a new piece of equipment, or it could be a company that's actually interested in something that's novel that they've never had in the company before, so it could be two clients working together -equipment manufacturer together with a client that wants to produce food. Really what we're doing is bringing in the microbiology element where we're deliberately challenging the item in question to show that it is adequate for what they want, what sort of food product they want to produce, so the whole range of different clients that can actually benefit from doing work in this microbiology process hall.

The hall can contain a whole host of different types of equipment. This depends on what the client is wanting to have an evaluation of, so it could be somebody that's focusing on and showing a particular log reduction of a certain organism. It could be one part of the whole manufacturing system or it could be several separate units for example and you could identify different log reductions at different stages. It could be something that's part of the preparation stage, something as part of the cooking stage, or the final end bringing together of all of the ingredients as a packaging step. It's available for a whole host of different types of equipment that that need to be evaluated.

We've done assessments of different initial concentrations, initial content of the organisms in them in the product, we've inoculated them into different formats as well, different positions in a food and also then assessing the manufacturing equipment itself, inoculating into different places, seeing if it's decontaminated by a particular type of wash technique.

There's a whole range of different activities that can be assessed and we've had some very successful work with the whole range of different clients.