Ensure product safety through process validation and challenge testing

4 March 2022 | Rob Limburn, Danny Bayliss, Annette Sansom and Andrew Collins

Food Business Operators (FBOs) must validate their microbial kill steps. When the process does not allow for the use of temperature sensors, or there is a lack of available data, microbiological challenge tests can be a valuable option, demonstrating the log reduction achieved by processing equipment and cleaning regimes.

Pathogen reduction

Pathogen reduction steps in the manufacture of foods are a key requirement for FBOs, with validation being an important method of showing the critical parameters to control the production of safe food. Monitoring temperatures of batch-processed heat-preserved products often give FBOs confidence that the process meets known inactivation kinetic requirements for specific microorganisms. For example, the pasteurisation of a chilled product at 70°C for two minutes should achieve a 6-log reduction in Listeria monocytogenes which causes listeriosis, thereby ensuring that the product is safe to be stored chilled for up to 10 days.

Log reduction of microbes cannot always be correlated with time and temperature. Instances where these parameters are not an accurate measurement include:

- Processes to remove microbes from the surface of food commodities like tinned and bottled goods, fresh goods (meat, fish, fruit, dairy), dry goods (grains, rice, nuts, seeds, spices, herbs), refrigerated and frozen goods and ready-to-eat products.

- Products in which characteristics such as water activity (aw) or moisture constantly change during processing.

- Products treated with emerging processes where there is a lack of data to draw from.

- Situations in which the factory environment is the focus of an antimicrobial treatment.

Key considerations for choosing a validation partner to undertake challenge testing

What is challenge testing?

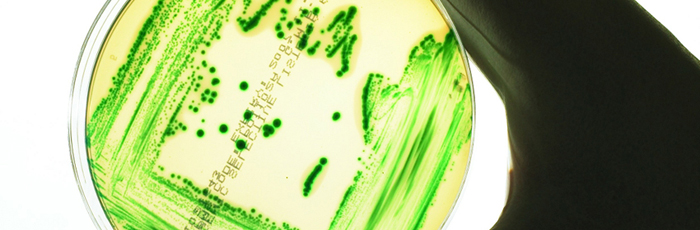

Challenge testing involves the inoculation of a product or an environment and the subsequent study of microbial inactivation, to demonstrate the impact of conditions that the product has been exposed to (processing or cleaning regime).

5 top questions that you need to consider

With many institutions and laboratories offering challenge testing services it can be difficult to choose between them. It is worth noting that there is an increasing number of published guidance documents on challenge testing which describe commonly accepted practices. The cheapest option is not always the best, as there may be trade-offs with the quality of service suffering as a result.

When you receive a proposal, put your analytical hat on, and ask yourself:

- Will the methods be rigorous, accurate and representative?

- Will the results be repeatable?

- Will the full range of possible conditions be considered? Will the worst-case scenario for microbial survival be investigated? Are current processes capable of removing microbes in this situation?

- Is the advice going to be useful and will the source of any advice be reliable?

- Will I be confident that the results show that processes and regimes are achieving sufficient inactivation of pathogens?

Challenge test design

The design of tests is as fundamental to the safety of your process as the choice of processing equipment. Unfortunately, not all challenge tests are equal. Incorrect methods can lead to substantial under- or over-estimation of lethality. Tests should be undertaken by specialist microbiologists. The basic principle of a challenge test is extremely straightforward. Microbial challenge testing is undertaken by deliberately inoculating food, drinks and environments with microbes to find out if thermal and non-thermal antimicrobial processes, such as pasteurisation, or regimes, such as disinfection, are effective at removing potentially threatening organisms.

Microorganisms in the food industry

The types of organisms that you should be aware of are:

- Viruses – this health risk can exist in food (e.g. norovirus) or the air (e.g. SARS-CoV-2)

- Mould – often an indicator of spoilage

- Yeast – often an indicator of contamination

- Bacteria – this health risk includes species like Salmonella, Listeria, E. Coli and Clostridium botulinum.

Key considerations of challenge testing

Challenge testing processes

Process settings should represent real-life.

The following should be considered:

- lowest residence time

- lowest lethal factor (e.g. temperature, pressure or dosage)

- highest feed rate

- highest throughput

- highest product loading

- lowest steam percentage /mixing

Product characteristics should be considered and remain unaltered by inoculation.

The following should be considered:

- low moisture

- low aw

- particulate size

- heat penetration/flow characteristics

- surface features

- fatty/low moisture areas

- neutral pH, high Brix level

- high total solids levels

In addition, samples should be representative of a naturally contaminated product and the inoculation process should not alter the physical attributes of the sample.

Sample placement should be representative.

Temperature distribution analysis should be undertaken to identify cold areas, spots or channels present in thermal processing equipment, allowing challenge test samples to be directed to the areas receiving the least severe process.

Samples should reflect products to show a ‘real’ response to processing.

- If the product is surface-contaminated, samples should be surface- inoculated.

- If the product is dry, inoculated samples should be dried to the same aw/moisture level.

- If a product is contaminated throughout, the samples should be contaminated homogenously.

- In a process, samples should be introduced to the whole process and retrieved as soon as possible after, with additional lethality avoided (e.g. samples sitting at high temperatures post-process).

Surrogate microbes should closely match pathogens in terms of characteristics and response to processing.

When no published information is available for a specific product to support the suitability of a surrogate in a processing scenario, it must be experimentally confirmed.

Challenge testing environments

Environments should be real-to-life

If a challenge test is being undertaken in an aerobiology laboratory, then conditions should be reflected in the experiment design.

Regimes should represent real-life.

The following should be considered:

- temperatures

- humidity

- disinfection times

- the dosage of treatment

- the environment the treatment is being applied to

- equipment touchpoints

Surrogates.

Surrogate microbes should closely match pathogens in terms of characteristics and response to the lethality of the process or cleaning regimes used.

When no published information is available for a specific product to support the suitability of a surrogate in a processing scenario, it must be experimentally confirmed.

How we can help

Campden BRI have the expertise and resources to undertake off-site and on-site validation of processes. As expert in process validation and challenge testing, we understand the key considerations (as described above) and can provide a thorough, bespoke proposal, undertaking challenge testing with a conscientious regard to all factors.

We consider the nuances of processing food and the factors that may influence challenge testing, such as the variability involved in the vast array of different processes, regimes and products. With this in mind, we can advise on and undertake industry standard challenge testing (in accordance with current best practice) or enhanced testing for situations where there are higher degrees of variability.

At Campden BRI we have:

- A versatile, interchangeable containment level 2 (CL2) process hall in which we can test different pieces of equipment and different microbes (the exact species of concern or a surrogate).

- A wash tank to trial the washing of vegetables in chlorinated or ozonated water.

- An aerobiology lab in which we can undertake challenge tests on airborne pathogens and validate air cleaning systems.

- Microbiology scientists who have a wealth of experience in the food and drink industry and who understand challenge testing, the nature of key microbes and their surrogates and how processing and selective agents in growing media can influence results.

- Presence on ISO TC34 / SC9 / WG19 which is currently developing guidance on inactivation challenge testing.

- New technology experts that understand how to run challenge testing and who can attend your site to ensure that your set-up is correct and refined for its purpose. We can validate high-pressure processing (to 6,000 bar pressure), UV-C, Pulsed Electric Field, Revtech, Cold Plasma and much more.

- Expertise in the practical application of food safety management and good hygiene principles, including HACCP and BowTie methodology.

When we undertake on-site validation, we also factor in the way challenge test samples are stored and transported, ensuring that samples stay in ‘stasis’ and the microbes within them do not grow or die off.

We can also include ‘transport controls’ which are inoculated samples taken to the site of a challenge test, stored in the same way as the challenge test samples (but not exposed to the process or regime) and analysed to demonstrate that transportation has not influenced the challenge test samples.

Our validation experts

About Rob Limburn

Rob has worked in Microbiology here within both Methods Research and Industrial Process Microbiology. He has been working in the food industry since 2004 and also has experience in allergens testing and authenticity testing.

About Annette Sansom

Annette has a wealth of knowledge and experience from working at Campden BRI since 1998, always within Microbiology.

Annette’s food and drink industry interests are: microbiology including bacteria, viruses, fungi and protozoa; food safety; food spoilage; fresh produce microbiology including vertical farming and methods to describe microbial populations.

About Andrew Collins

Andrew joined Campden BRI at the beginning of 2009. With over 30-years’ experience in a wide range of food businesses (including catering), his current role focuses on consultancy work with the holistic and practical application of food safety management including the role of HACCP and good hygiene practices.

He is a certified BowTie practitioner, and is one of the few food safety experts globally using BowTie methodology – a barrier, risk-based thinking approach to risk management in the food businesses. This approach enables businesses to build holistic, resilient and adaptive systems in a rapidly changing environment.

Andrew also works on supply chain management, agriculture and water use, animal feed and traceability. Plus, he’s part of the team that manages hygiene and allergen management.

How can we help you?

If you’d like to find out more about validated processes, contact our support team to find out how we can help.

Are you a Campden BRI member who attends the MIG meetings?

- If not, you’re missing out on a whole host of exclusive benefits such as learning from industry-leading experts and networking with peers to overcome your challenges.