Core technologies

High pressure processing

What is high pressure processing?

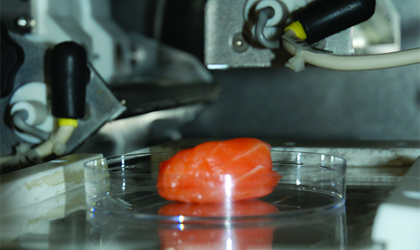

High pressure processing (HPP), as currently used commercially, is a non-thermal pasteurisation process in which a food is subjected to pressures of about 150 to 600MPa (1500 to 6000 bar) for a given period of time. Pressure generation is mechanical, through a fluid (water), which is consequently transmitted to the product. There is usually a volume reduction of around 12% (resulting from the compressibility of water) as pressure is applied, this is reversed when the pressure is released. A small temperature rise is observed as a result of compression that is typically around 3-4°C per 100MPa of applied pressure but can vary depending on the food product.

How high pressure processing can help the food and drink industry

The high pressures used for HPP can inactivate vegetative microorganisms, yeasts, moulds and certain enzymes. The extent of microbiological inactivation is affected by many factors including the intrinsic properties of the food such as its pH, water activity, fat content, protein content, mineral and sugar content, bacterial growth phase and the pressure, temperature and time combinations that are applied.

The, essentially, non-thermal nature of high-pressure pasteurisation makes it an excellent process for preserving the ´fresh–like´ characteristics of foods. Unfortunately, bacterial spores are very resistant to commercially achievable pressures. As a result, products that are currently on the market tend to be chilled and/or contain additional preservation hurdles such as pH, water activity control or other combinations of factors that have been demonstrated to prevent the growth of spores such as psychotropic strains of Clostridium botulinum.

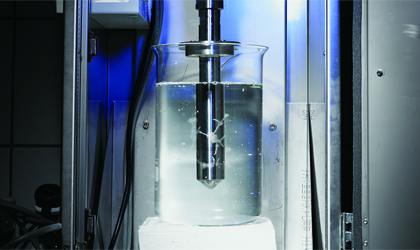

How we can help you with our HPP system

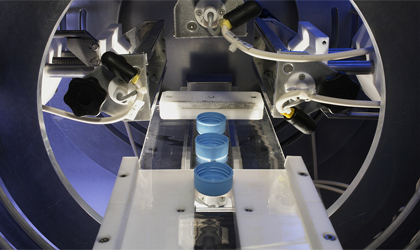

We have an EPSI High pressure system with a 700ml capacity situated in a class II lab for lab scale validation, challenge tests and product suitability trials. Our system is set up to vary the time to achieve target pressure and decompress quickly to be as representative of commercial systems as possible which is especially important for validation testing. We can partner with contract processors should clients wish to explore full scale production trials.

Please visit the new technologies training page if you are interested in bespoke training for HPP.

More on high pressure processing

Case study: Exploring the potential of high–pressure processing

When Heartwarmer Foods learnt of the Technology Strategy Board's £5K research funding vouchers, they came to us to help them assess the potential for high pressure processing (HPP) of their novel fruit smoothie products.

Publication: Guidelines on good manufacturing practice for high pressure processed foods

Ensure that you understand the key characteristics of high pressure processing, and take advantage of this major opportunity for producing high quality, safe food.

Video: High pressure processing

High pressure can be used not just to pasteurise food products, but also to change their characteristics.

Pulsed light

What is pulsed light?

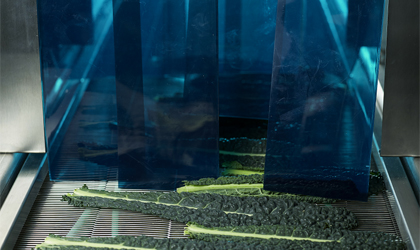

Pulsed light is a surface preservation method in which a material is subjected to very short pulses (of the order of milliseconds) of broad-spectrum white light. The spectrum of light is typically between 200 and 1100nm and includes UV, visible and infrared components. The product is typically exposed to 1-20 pulses having an energy density in the range of 0.01 – 50 J.cm–2 at the surface.

How can pulsed light help the food and drink industry?

Applications for pulsed light in the food industry include the decontamination of packaging surfaces. The technology is commercially used on a range of packaging materials for decontamination before filling. Applications for food are likely to include surface treatment of relatively short shelf-life products that are susceptible to mould growth such as baked goods. A relatively modest reduction in microbial numbers could offer a significant shelf-life extension for very short-shelf life products. Pulsed light systems are also being used to modify the nutritional composition of products such as mushrooms to boost Vitamin D2.

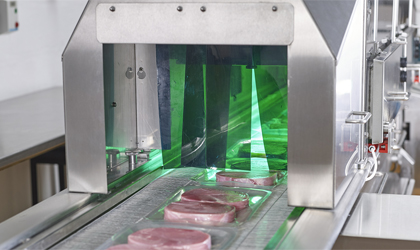

Trials at Campden BRI have determined that a 1-3 log reduction in total viable counts is typically achievable on food surfaces such as meat, cheese and fruit (R&D 281) and similar results have been reported by other groups.

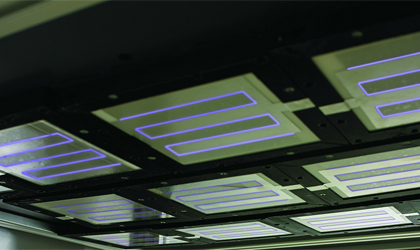

How we can help you with our pulsed light system

Campden BRI currently can access pulsed light systems for companies to trial the decontamination effects or product nutritional changes. Get in touch today to find out how we can help your business.

More on pulsed light

Video: Pulsed Electric Field (PEF)

In this short video, Danny Bayliss, New Technology Lead at Campden BRI, discusses how using new technologies can help you unlock smarter ways of working.

Podcast: Pulsed light technology for surface decontamination

Pulsed light food processing is the use of very short pulses (of the order of milliseconds) of broad-spectrum white light to decontaminate surfaces and transmissive materials such as water.

Case study: Pulsed light processing

The technique, which has been shown to be effective against bacteria, spores, yeast and moulds, involves flashing surfaces with intense, short duration pulses of broad spectrum white light.

UV-light

What is UV-light?

Ultraviolet (UV) light treatment is a non-thermal, non–chemical technology to inactivate microorganisms. It has been used for many years to disinfect water/air systems and to decontaminate surfaces (packaging/work surface). UV light is part of the electromagnetic spectrum and lies within the range of 100 – 400nm. It can be subdivided into three categories: UV–A (from 315 to 400nm), UV–B (from 280 to 315nm) and UV–C (from 100 to 280nm).

Although all UV wavelengths cause some photochemical effects, wavelengths in the UV-C range are of particular interest due to their germicidal effect. The RNA, DNA and proteins of cells (including microorganisms) absorb the wavelengths which causes damage and, ultimately, cell death.

Ultraviolet light is applied worldwide for the disinfection of drinking water, wastewater, process water and industrial effluent and is gaining more interest across the whole spectrum of food and beverage industries. Current industrial applications include the treatment of conveying lines, packaging, containers, as well as food product surface decontamination such as fruits or vegetables.

How can UV light benefit the food and drink industry?

Treatment with ultraviolet energy offers several advantages for food manufacturers, for example it:

- Can deliver microbial control and maximise product quality without the use of temperature, chemicals and water

- Does not leave a residue or require extensive safety equipment

- Is easy to use

- Can be used to improve shelf-life without compromising on the product quality

- Can offer greater safety levels in microbial control without compromising throughput (for transfer systems)

- Can enhance Vitamin D levels in some products such as milk, mushrooms and bread.

How we can help you with our UV light system

We have an ultraviolet light tunnel system and a water treatment liquid system on site for research and private contract services. Get in touch today to find out how we can use our system to help your food business achieve its goals.

More on UV-light

Blog: Decontaminating with UV-C light? Here’s what you need to know

As this technology grows in popularity, it’s important to build your understanding of how it can be applied safely and how it can help you.

Project: New technologies for food manufacturing

The focus for this project will be on emerging technologies for improving quality and value and will conduct feasibility studies on commercially relevant emerging technologies.

Video: UV light tunnel

This video clip demonstrates Campden BRI's UV light tunnel, in which product can be treated from both above and below.

Power ultrasound

What is power ultrasound?

Power ultrasound (typically in the range of 20kHz to 100kHz) has numerous non-preservation applications such as cutting, cleaning, emulsifying, de-gassing, foam breaking, improved mass transfer and more uniform crystallisation. Ultrasound could prove very useful as a tool for augmenting conventional heating processes and is already being used for this purpose in some food processing facilities. The technology can induce permanent and, in some circumstances, reversible viscosity modification which can improve the efficiency of down-stream processes that are limited by viscosity. Examples include spray driers, filtration and batch or continuous-flow heating operations.

How can power ultrasound help the food and drink industry?

Power ultrasound can help manufacturers speed up processes. Whether it is the speed of carbonated beverages lines and reducing spillages, improving extraction time, reducing cleaning time or minimising hydration time, it’s likely this technology can help. It is also very versatile and offers a range of benefits for manufacturers with short ROIs (return on investments).

How we can help you with our power ultrasound equipment

We currently have power ultrasound equipment from Cavitus on site for use in research and private contract work, that can be operated in a continuous flow or in batch mode. We have recently explored the use of power ultrasound to assist in brewing applications with improved extraction.

More on power ultrasound

Video: Power ultrasound technology in food processing

Power ultrasound is a versatile technique which has many applications in processing and is effective in microbial inactivation.

Podcast: Emerging technologies

Craig Leadley talks about emerging technologies such as high pressure processing, ohmic heating and power ultrasound, and how these can help with 'clean label' product reformulation.

Cold plasma

What is cold plasma?

Cold plasma is otherwise referred to as the 4th state of matter. When you apply enough energy to a gas, a plasma discharge can be achieved. It is estimated that 99% of the known universe is in a plasma state. Man-made plasma can be generated at low temperatures typically by applying a voltage to a gas. The excitation of the gas into a plasma state can generate an abundance of highly reactive chemical species which are capable of inactivating a wide range of microorganisms including food borne pathogens and spoilage organisms (hence the possible food industry applications). The diffuse reactive species revert back to an inert gas atom once the applied voltage is removed.

How can cold plasma help the food and drink industry?

The potential for cold plasma has not yet been realised in the food industry, but there are a lot of promising applications that provide significant benefits. The most noticeable application is the disinfection of surfaces in a particular equipment, packaging, food contact surfaces or even food itself. Compatibility with food products could allow shelf-life extension or online disinfection of processing equipment to reduce cross-contamination and the establishment of biofilms on equipment. Plasma treatment requires no liquids making this technology an ideal disinfection tool for manufacturers of low water activity products.

Our experts have a wealth of experience using this technology. Feasibility studies using this technology for surface disinfection have been conducted as part of our member funded research programme . We’re also industrial sponsors of a PhD exploring plasma systems for rapid continuous decontamination and are a partner on an Innovate UK project supporting the development and testing of a plasma aseptic packaging machine.

How can we help you with our cold plasma system?

We currently have a cold plasma system on loan from Liverpool University which is available for research and private contracts. With our extensive experience with this technology, find out how we can use it to help you – get in touch today.

More on cold plasma

Podcast: Cold plasma inactivation of food microorganisms

Danny Bayliss talks about how problem microorganisms can be inactivated by exposure to cold plasmas.

Video: Cold Plasma

Although cold plasma is not yet established in the food industry, it offers potential applications that could have significant benefits, as this video clip demonstrates.

Revtech processing

What is Revtech processing?

The Revtech processing system is a device for pasteurising low water activity products using electrically-heated coils and, when required, the addition of steam.

How can Revtech processing help the food and drink industry?

The technology allows manufacturers to process and pasteurise their ingredients or products to ensure they are safe and free from Salmonella. It can allow functionality changes in products, stabilises a product’s moisture, develops different colour profiles during roasting or toasting applications and can pop cereal and rice. The benefit for here is that roasting without gas burners offers greater safety.

Dry products such as: herbs, spices, nuts, seeds, grains, dried fruits and vegetables, cereal mixes and animal feed can be treated with this technology. While its suitable for processing dry food products, not all products have been validated for each piece of equipment.

How can we help you with our Revtech system?

We currently have a Revtech system onsite for the continuous heat treatment of herbs, spices, nuts, seeds, powders and other dry ingredients. The system incorporates electrical heating with optional heated steam followed by a drying step to remove moisture before packing. The product is conveyed through the tubes of the machine via vibration. The option for re-circulating is available if roasting is required. This machine is specially designed for research on food safety and the development of new products. Find out how we can use it to help you – get in touch today.

More on Revtech processing

Video: Pasteurisation of dried ingredients

The pasteurisation of dry ingredients requires specialised conditions, as traditional water/steam-based heating systems are not appropriate.

Technology training courses

Explore our food technology related courses including; Food technology for non-food technologists and Beverage development and manufacture

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079