Particle shape and size

Vince Clark, Analyst

Physical properties of food and drink products affect their taste, texture, appearance and stability, and depend on the properties of raw materials and ingredients. Particle geometry can be used to assess quality control and quality management, and ultimately product performance.

Vince Clark (Analyst) explains how the particle size and shape, both of ground materials and of particles, and droplets in liquids, can be analysed using state-of-the-art methods to aid product development, reformulation and quality control.

You may also be interested in

Transcript

Particle shape and size analysis is exactly what it says on the tin, it's the measurement of the size and the shape of particular particles within a sample.

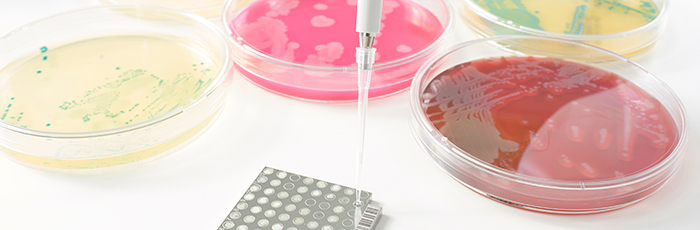

It can answer quite a few questions for clients within the food industry, one of the main ones being around quality control and quality management - are you producing your product at the right particle size and does it have the right particle size distribution? This is important later on in the line as it can affect performance. This could also be to do with what ingredients be supplied to you - you could check on your supplier, is the particle size of their ingredient correct? We also have issues in beer in terms of emulsion stability or suspension stability. All of these things can be checked with particle size analysis. It can be used to analyse a wide range of samples depending on the piece of equipment we're using, it can measure from 10 millimetres all the way down to a couple of nanometres. This is a wide range of particles and you can work with both dry samples and wet samples - dry samples such as condiments of herbs, spices, sugar, salt, flour even up to the cereals of millet and wheat, but also wet samples, both oil-based and water-based, creams, orange juice, beer those kind of samples can all be tested on different pieces of equipment.

We have a range of equipment here at Camden BRI that can do this, we have dynamic image analysis, mechanical sieving, air jets sieving, DLS, electro zone and laser diffraction. These all cover particular niche areas of the sample zone.

Some of the common practical applications of this analysis could be to do with flour and semolina. These both have specifications in terms of being a particular particle size. Flour, in particular wheat flour when it goes onto baking needs to be a particular particle size because it affects the baking performance later on in the process.We also have issues in terms of the pulp within orange juice or fibres within fruit smoothies. These are things that the client is interested in getting within a particular band of particle size ranges. Another example of one of its uses is fractionation techniques, we can take the particle size distribution of, for example, potato flour and it'll have a distinct peak where the starch molecules are compared to the other flour molecules. We can then look between that peak and pick a particular particle size for the sieve to separate the two, so we can collect the starch molecules on their own. A further example of how this to be used is if a client comes to us and they're looking to change their process for their current products and they want to make sure that the particle size of their products coming out is exactly the same as it was before or close enough within tolerance.

So far, I've just been talking about size distribution and analysis, but dynamic image analysis can also test shape, we can look at the shape of individual particles within a sample. One of the uses we used this for was for millet grains. Millet grains, normally, are fairly spherical in their whole form but when broken they are less spherical. We can give the grains a number related to this to see how close they are to a sphere. That way when testing the sample we can see the proportion of broken and whole grains.