BRC Global Standard for Food Safety Issue 8

To discuss your needs

The BRC Global Standard for Food Safety was updated with the release of Issue 8 in August 2018. The first audits against this issue were conducted from 1 February 2019.

What are the main changes?

- New sections – production risk zones and traded goods

- Food safety and quality culture – compulsory requirement

- Separate clauses for supplier approval and monitoring – clause 3.5.1.2 for supplier approval and clause 3.5.1.3 for ongoing supplier monitoring

- Food defence needs to be risk assessed, defined, documented, controlled, monitored and reviewed – clauses 4.2.1, 4.2.2, and 4.2.3

- Risk based programmes for environmental monitoring – clause 4.11.8

- The need to validate cooking instructions and shelf-life

- Training on labelling procedures

- Cyber security related to documents, records and equipment settings

- Understanding the significance of laboratory results

- Traceability procedures

- Defining root cause analysis

Overview of main changes?

Guide to the key changes to the standard

Video: Richard Leathers discusses Issue 8 changes

Slide presentation: Issue 8 – what can we expect?

Now available

- New webinar BRC issue 8. The BRC Global Standard for Food Safety is the most widely used of the commercial standards for assuring the safe production of food and drink. Issue 8 is the new update, which was released on 1 August 2018. The first audits will be conducted from 1 February 2019. This webinar outlines the key changes within the new document.

- New Guideline 72: TACCP second edition 2019 Guideline 72 has been revised to reflect the changes in food fraud and food defence, with considerations to updates in standards, retailer requirements, reference documents and other relevant sources.

You may also be interested in

- Phil Voysey discusses how to meet the new BRC Issue 8 environmental monitoring requirement.

- Sign up to our food safety assurance newsfeeds.Use our preferences page to choose the information you want to receive.

- Join our quality and food safety management member interest group (members only - free to attend). Keep ahead by networking with colleagues at our regular interest group meetings

- White paper: Traceability in the food and feed chain

- White paper: Food safety culture

- Blog: Good hygiene starts with kitchen design

- Training: Food defence

- Training: TACCP Courses

- Training: HACCP courses

Key services

HACCP in manufacturing

Our HACCP products and services are based on extensive experience helping with the development and implementation of HACCP–based systems.

CLAS (Campden Laboratory Approval Scheme)

Leading scheme for laboratories. Established specifically to meet the need for a recognised standard for food, drink and allied laboratories.

Retailer supplementary audit (RSA) scheme

Drives delivery of consistent, accurate, reliable, defendable and timely results for the benefit of retailers and their suppliers.

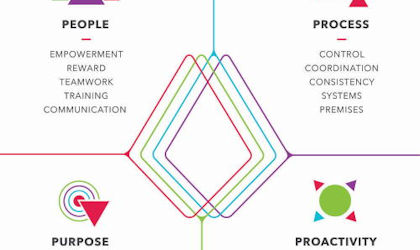

Culture excellence

The Culture Excellence Program is a unique solution for the measurement, analysis and improvement of safety and quality culture.

BRC 8 training courses

Explore our BRC 8 related courses including; Cooking (heating) instruction development, HACCP and TACCP

Are you getting the most from your Membership?

Watch our membership FAQ videos and find out more about Member Service Account spending, Member Interest Groups, help and advice

Where we refer to UKAS Accreditation

The Campden BRI group companies listed below are accredited in accordance with the recognised International Standard ISO/IEC 17025:2017 by the United Kingdom Accreditation Service (UKAS). The accreditation demonstrates technical competence for a defined scope of methods, specific to each site, as detailed in the schedules of accreditation bearing the testing laboratory number. The schedules may be revised from time to time and reissued by UKAS. The most recent issue of the schedules are available from the UKAS website www.ukas.com. Campden BRI (Chipping Campden) Limited is a UKAS accredited testing laboratory No. 1079