Revised food safety guideline

26 February 2021 | Support Team,

Phil Voysey, senior microbiologist at Campden BRI and editor of the revised food safety guideline, discusses the importance of a guideline on cleaning and disinfecting food factories, and the approaches taken to update one already in circulation.

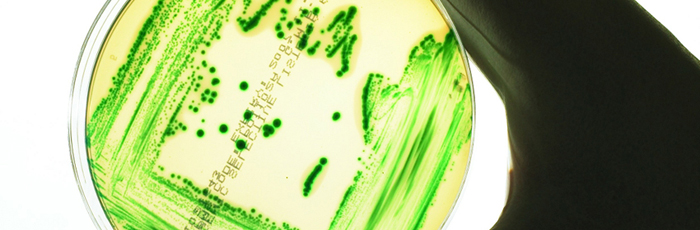

The coronavirus pandemic has seen factory cleaning prioritised like never before, but even prior to the public health crisis food businesses needed to comply with the EU regulations related to the hygiene of foodstuffs to remain in business. Ensuring factories are cleaned and disinfected effectively is a fundamental prerequisite for the safe production of food and drinks. This involves decisions on when to clean, how to clean and what chemicals to use to remove physical, chemical and microbiological contaminants.

For many years, cleaning chemical suppliers helped food manufacturers design and implement their cleaning programmes, including writing cleaning schedules with them. This all came as part of the service package that the chemical suppliers would provide along with their cleaning products. This is a service that they still provide, however, with the introduction of a comprehensive guideline, manufacturers have acquired a little more independence.

In order to capture best industry practice for cleaning and disinfection of food factories, in 2008 we put together a working party of food manufacturers and cleaning chemical suppliers. These professionals produced Guideline 55: Cleaning and disinfection of food factories: a practical guide. The impartial advice in the guide reflected on the principles of how to produce and operate effective cleaning schedules and plans, which could be applied in a consistent way across the food industry. It enabled food manufacturers and chemical suppliers to understand the theory as well as putting this into action in facilities that they were familiar with.

The guide helped industry understand various aspects to cleaning and disinfection, including:

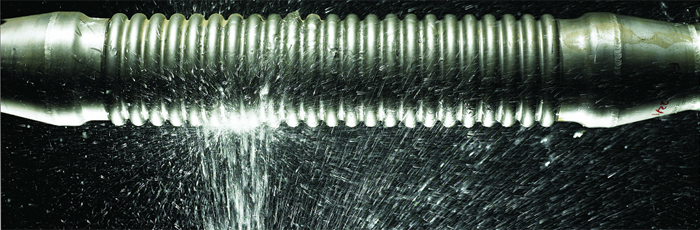

- how to select the appropriate chemicals – based on differences in equipment, facilities and ingredients / foods being handled

- the various methods of cleaning and disinfection

- how to build cleaning schedules

- the timing and frequency of cleaning

- the order in which different stages of cleaning and disinfection should be carried out, and

- how to monitor factory cleanliness

The importance of a standardised guideline

The first edition of Guideline 55 helped food manufacturers comply with the EU regulations 852/2004 on the hygiene of foodstuffs and 853/2004 laying down specific hygiene rules for food of animal origin. Complying with these regulations is essential if a manufacturer wants to remain in business.

In putting the guide together, members of the working party were able to come to a consensus on the best approaches of cleaning based on their personal experiences. As a result, the guide became comprehensive by covering areas such as how to clean particularly tricky areas including drains and floors. It also dealt with errors that are commonly made. In some cases, hygiene staff in food companies were able to use the guideline as a definitive ‘authority’ on approaches to specific hygiene-associated issues, thereby giving them leverage for persuading management that their approach to an issue was the most appropriate, even if it meant management spending money!

The guideline also helps the industry consider the costs and consequences of not cleaning properly and/or frequently enough. As well as protecting the consumer, it has an economic basis in the prevention of product loss due to microbial spoilage

Guideline 55 highlighted how soiling of surfaces and equipment is unavoidable but put focus on the practical ways of preventing these residues from accumulating. With this guide, food manufacturers gained a level of independence, in the sense that they were not reliant solely on their chemical supplier for definitive information on the practices they needed to follow. Having the document readily at their disposal, with instant access to guidance, manufacturers were able to regularly adapt their cleaning processes as their factories developed. Now it is Guideline 55 itself that is adapting.

Updating Guideline 55

Since publication of Guideline 55, a number of changes have been made in the management of hygiene in food production. It is essential that the guideline aligns itself with these changes to reflect the most up to date thinking, research and developments in cleaning and disinfection. With this comes new legislation and chemical cleaning products that the industry must comply with and be aware of.

For example, new controls have been introduced concerning sanitation, such as those in the US, under the Food Safety Modernization Act. In addition, the British Retail Consortium (BRC) has requirements concerning cleaning (both microbiological and allergens). Cleaning is also included as an integral part of the food safety management system in the Codex Alimentarius. The guideline needs to align itself with the new cleaning chemicals and techniques that have become available, and products that are no longer used. This has also been coupled with the production of different product types, equipment and methods.

The one-year project

To remain relevant and up to date, we’ve updated Guideline No. 55: ‘Cleaning and disinfection of food factories: a practical guide’. The update came as part of a one-year project funded by our members.

The project took a number of approaches to ensure the guideline remains the comprehensive go-to document. The approaches included:

- forming a consultative group of industry and Campden BRI specialists who met throughout the project’s duration, and

- researching literature and regulations to collate the most current practices and guidance in cleaning and disinfection

The project also included a practical element: the creation of short educational videos that advise on how to carry out key aspects of hygiene in production. They’re now live and include:

- cleaning a drain

- cleaning for allergen control

- producing a cleaning instruction card, and

- choosing the right detergent

Additional guideline for Listeria control

A second of our member-funded projects will follow a similar approach to this one. It will produce an up-to-date ‘one-stop-shop’ guideline document on controlling Listeria during food production.

As 2018 saw the largest listeriosis outbreak ever recorded, the need for this guideline became clear. Listeria monocytogenes-contaminated South African polony sausage caused 200 deaths and it became apparent that the food industry still does not have the measure of this pathogen. This project will run for two years and the guideline will become available in 2021.

Guideline 55 (Second edition) now available

The guidance document - Guideline 55: Cleaning and disinfection of food factories: a practical guide (Second edition) 2020’ - has now been released and is available to purchase. Members of Campden BRI will receive an exclusive discount.

How can we help you?

Do you need help understanding food safety? Contact us to find out how we can help.