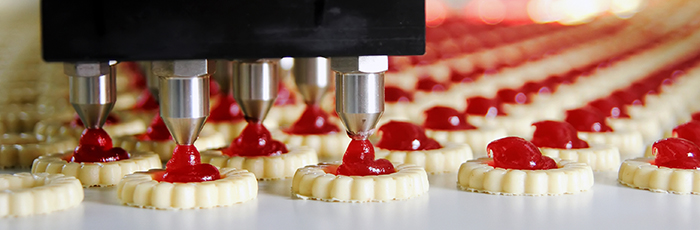

Creating the texture that consumers want from plant-based alternatives to meat

8 March 2023 | Amy Voong, Senior Food and Drink Microstructure Scientist. Gemma Dale, Special Projects Group Leader and Marleen Chambault, Sensory and Consumer Research Scientist

To understand the structural composition of meat-alternative products compared to meat, we have been visualising the microstructure of ready-to-eat meat and meat-alternative products by compound light microscopy.

The microstructure of food has a direct impact on texture and sensory perception.

The microstructure of food has a direct impact on texture and sensory perception. Therefore, an understanding of your product’s microstructure will help you to develop the desired texture that you and your consumers are looking for.

Under the microscope

Our Microscopy team can visualise the microstructure of meat and meat-alternative products by compound light microscopy. Through a process of precision sectioning and staining to highlight key structures, such as protein, adipose (fat) tissue and starch, we can create like for like samples of meats and meat-alternatives for comparison.

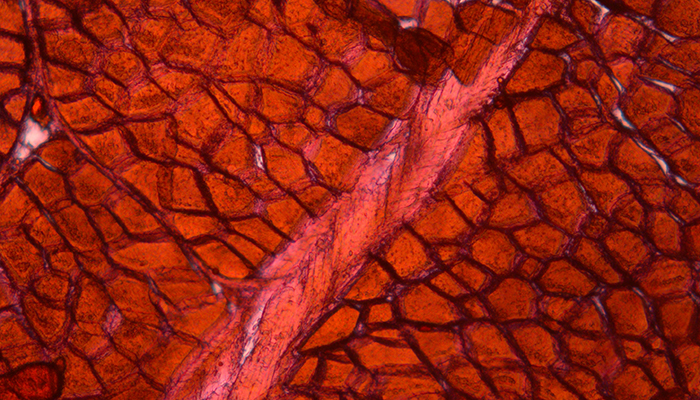

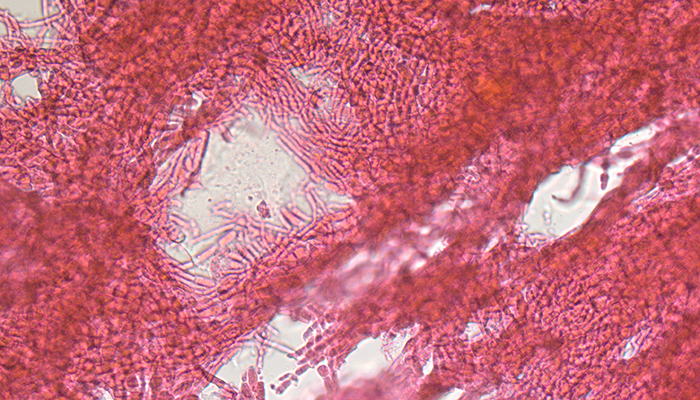

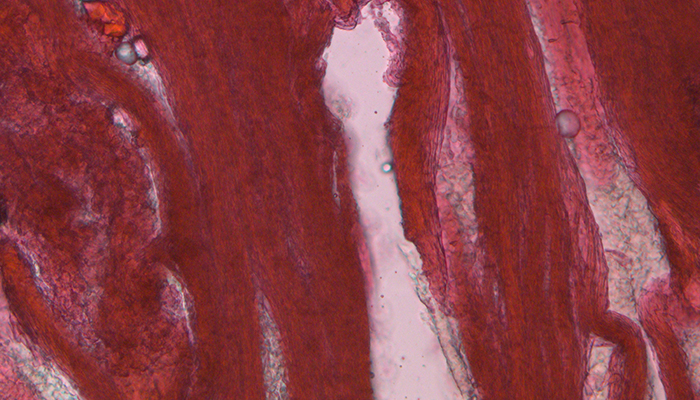

Below are example images of meat ham (Figure 1) and three different ham-style meat alternatives (Figures 2, 3 and 4). The images illustrate the differences in protein structure between mycoprotein, textured soya protein, and ‘globular’ soya protein based ingredients in three types of shop-bought meat-free hams, compared to a sample of cooked meat ham prepared in the same manner.

Figure 1. Ham meat

Figure 2. Ham-style meat alternative

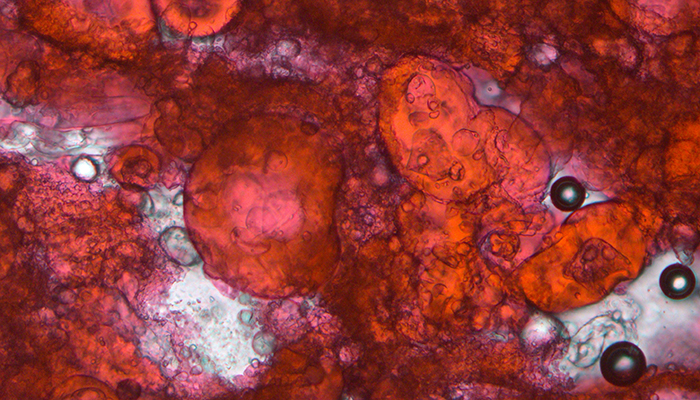

Figure 3. Ham-style meat alternative

Figure 4. Ham-style meat alternative

The image of the cooked meat ham shows protein structure in the form of muscle fibres (in cross-section) and central connective tissue. Eosin staining was used to highlight the protein content in all samples.

The mycoprotein (Figure 2) shows a mass of densely packed hyphae in a disordered arrangement.

The textured soya protein (Figure 3) has a fibrous configuration, which in terms of structural appearance best resembles muscle fibres and connective tissue as seen in the cooked meat ham sample, when compared to the two other meat-free protein types.

The ‘globular’ soya protein (Figure 4) features a less consistent structure and little fibrous content.

This information can support projects aimed at obtaining a better understanding of the sensory and texture characteristics that consumers enjoy in meat-free alternative products

A holistic approach – understanding consumer perception

One of our consumer research projects is investigating those sensory characteristics that consumers like and disklike about meat alternatives, focusing on a selection of commercial meat-free hams.

Using a temporal sensory technique called ‘Temporal Check-All-That-Apply’ (TCATA), consumers indicate the sensory characteristics that they perceive whilst consuming the ham samples. We then use statistical analysis to determine those sensory characteristics that drive or prohibit the consumers’ liking of the product (through the ‘liking’ scores also collected during the assessment).

The project is also looking at the impact of food pairing on acceptance of these hams (for example, whether the level of acceptance improves when the hams are consumed with bread and salad as opposed to on their own), as well as whether meat-reducers have different perceptions / expectations / liking of these meat-free hams compared to vegans, vegetarians and flexitarians.

We use a holistic approach to increase understanding of consumers’ perceptions of meat alternatives, which ultimately helps manufacturers optimise their products. The temporal sensory data and liking data collected with the consumers is typically analysed in conjunction with textural and microscopic data, enabling a deeper understanding of how microstructure and texture contribute to consumer enjoyment of such products.

Prior to this project, our Consumer Insights team had been collecting consumer feedback on a number of meat alternative products using both qualitative (online focus groups / communities) and quantitative (acceptance tests) consumer test approaches. Besides the TCATA method used in the multi-disciplinary research meat-free ham project, we have many other methods available to explore consumer expectations and experiences of meat alternatives right through all steps of the consumer journey.

Microstructural design is developing your product to achieve a particular structure

Product development through ‘microstructural design’

Microstructural design is developing your product to achieve a particular structure (microstructure – as seen under a microscope or using other microimaging technique) in order to achieve the texture / ‘mouthfeel’ that consumers want.

Textural perception and product performance of a food is largely due to its microstructural composition, as this dictates a materials physical and mechanical properties. Therefore, understanding how ingredients interact and behave during formulation and processing allows for microstructural design to achieve a desired texture.

The final microstructure of a product (when ready to eat) will influence its textural and sensorial qualities – as demonstrated by meat ham, within which a multi-component system of muscle fibres, connective tissue and adipose tissue provides its ‘meat-like’ texture. The muscle fibres within meat ham have an ordered alignment that enables contraction as well as stretching/elasticity. This is reinforced and strengthened by intramuscular connective tissue, thereby giving the meat ham structure a resistance to bite. In addition, the presence of intramuscular adipose tissue will have a role towards flavour, tenderness and ‘juiciness’.

By comparison, the disordered arrangement / lack of alignment of fibres in the mycoprotein sample image suggests little structure, therefore upon deformation (mastication; chewing), this sample is likely to impart a texture with minimal resistance (lacking ‘bite’).

In the textured soya protein, the proteins have been processed to create an aligned arrangement, resulting in bundles of fibres, which more closely mimic ham fibres. Therefore, upon compression or tensile force, this product is likely to impart more texture as the aligned fibres will create higher resistance to deformation – demonstrating the importance of microstructural design that is driven by texture and sensory consumer perception.

Your partner for successful product development

The information gained from imaging microstructure, alongside texture analysis and consumer insights, can provide valuable support for successful product renovation and innovation within the plant-based meat industry and the wider food industry as a whole.

We provide clients with clarity of how to achieve the sensory and texture characteristics that consumers enjoy, and can support you in leveraging these for the success of your products. We can help you to use this knowledge to overcome challenges with existing products and to develop new and reformulated products with success.

About Marleen Chambault

Marleen joined Campden BRI as a Sensory and Consumer Research Scientist in 2012. Marleen obtained her Food Science Engineer diploma (equivalent to a Master’s degree) in Agri-food Business and Management from Agrocampus Ouest in France (now Institut Agro Rennes-Angers) in 2008.

Before joining Campden BRI, she worked for several large companies in France, Belgium, the USA and the UK, where she gained extensive experience in R&D, Research and Sensory and Consumer Science.

After contributing to the development of sensory and consumer research capabilities at Campden BRI for 12 years, she now provides specialist statistical and methodological support to a number of technical teams across the business, in addition to lecturing on the various training courses relating to sensory science, consumer research and statistics.

How can we help you?

Understanding ingredient functionality – what each ingredient does for your product, and how – gives you the power to improve your products and processes, save money and time, and select ingredients that are right for you.

Are you a Campden BRI member who attends the MIG meetings?

- If not, you’re missing out on a whole host of exclusive benefits such as learning from industry-leading experts and networking with peers to overcome your challenges.