Highlights from the 8th Global Food Safety Training Survey – the industry can and should do much better

17 April 2024 | Bertrand Emond, Culture Excellence Lead

This is our 8th Global Food Safety Training Survey organised with Intertek Alchemy in collaboration with BRCGS, BSI, Intertek, SGS, SQF, TSI.

The survey was set up in 2013 to respond to the need for benchmark data in training practices, so that participant and other companies could compare themselves and share best practices.

Here we summarise the 2024 key findings. We also outline the biggest training challenges that were highlighted by the survey, as overcoming these could facilitate significant improvement for individual businesses and the industry as a whole.

Who took part in the survey and what it covered

Responses received were from over 3000 sites worldwide, covering a wide range of sectors and company sizes within the world of food and drink and beyond. Almost 3/4 participant businesses were in food and beverage manufacturing. The others were from associated industries, such as agriculture, packaging, distribution, retail and food service.

The survey covered: budget; amount of training (for staff, supervisors and senior staff); competency framework and training needs analysis; how training is delivered and reinforced; how training records are documented and managed; training goals, needs and challenges; impact of training; onboarding; the role of supervisors; cross-training; professional development; food safety culture; and advanced training technologies.

What the survey findings say about training in the food and drink industry

A sobering takeaway for the industry is that many were not following best practices and are settling for mediocrity or the bare minimum – a finding that has concerningly changed little since the survey was first launched.

Specifically, the key findings were as follows:

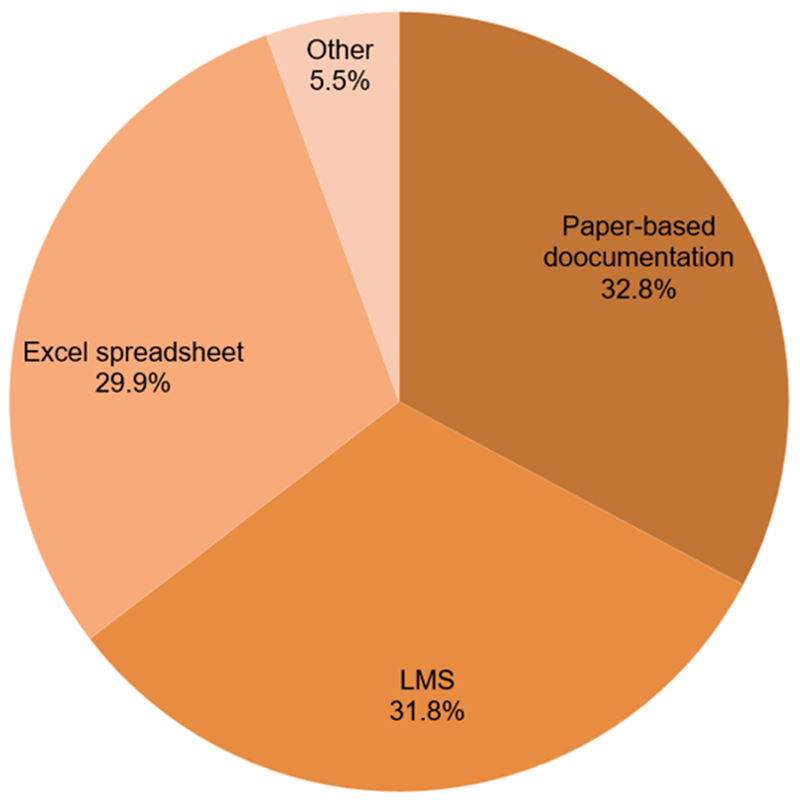

- Documenting and managing employee training records:

- Staggeringly paper-based records are still being used by nearly 1/3 respondents, closely followed by the Excel spreadsheet.

- Only 1/3 use a Learning Management System or other IT solutions

Documenting and managing employee training records

- Using a competency framework defining knowledge, skills and behaviours required for each job role:

- 1/4 still do not use a competency framework.

- Using training needs analysis / assessment to identify training needs, gaps and priorities for each employee:

- Only 2/5 use training needs analysis, with the remainder reporting “no” or “not sure”.

- Learning management / training team includes cross-functional team members to ensure training programme meets the needs

of the entire organisation:

- Only 2/3 do this.

- Using examples from own production facilities (photos, videos, instructions, etc.) to ensure the training reflects the

work environment where the employees will be performing their work:

- Only just over 2/3 do this always / often.

- Using continuous and updated analytical data to assess training effectiveness and guide continuous improvement in

training content:

- Just under 1/2 do not.

- Having a dedicated programme for cross-training for production employees to add flexibility and resilience to the

operations (staff have been trained to do different jobs):

- Only around 1/4 use cross-training regularly.

- Having a programme for professional development / career-path development for production employees:

- Only 1/5 have an established programme.

- Providing supervisors with leadership training:

- Although they have been identified as key individuals, over 1/4 do not provide supervisors with leadership training.

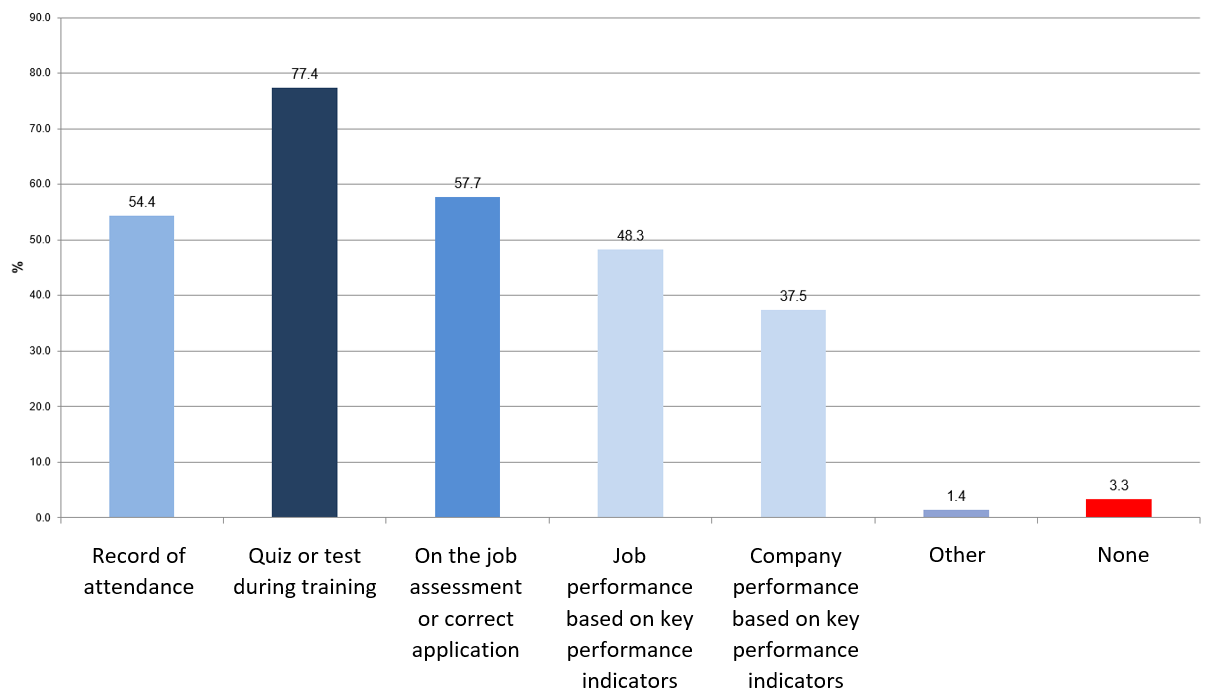

- Assessment of training comprehension:

- Just over 1/2 use ‘on the job’ assessment and just under 1/2 use a job performance assessment based on key performance indicators ( KPIs).

How do you measure comprehension?

- Use of advanced training tools / technologies:

- For each of Emotional Intelligence (EI), Virtual Reality (VR), Artificial Intelligence (AI) and Augmented Reality (AR), less than 1/10 reported currently using the technology.

- 1/4 are investigating AI.

- “Despite our training efforts, we still have employees not following established protocols on the floor”:

- Nearly 3/4 agreed or strongly agreed with this statement. This is one of the most concerning findings, especially as it has not changed over the last 10 years.

Despite our training efforts, we still have employees not following established protocols on the floor

Respondents’ views of their training programmes

Around 1/4 of respondents rated the quality of their overall training programme as poor and acknowledged that they could do better, with 3/5 rating it as sufficient (getting the job done). Interestingly, over 1/3 respondents think that their training has no impact on staff retention, with 1/10 thinking that it actually has a negative impact.

Worryingly, only 2/3 respondents think that their training programme has a positive impact on productivity, and 1/5 do not see any positive return on investment from their training programme. Furthermore, more than 1/ 5 do not have any clear vision for improving their training programme next year!

The biggest training challenges

Clearly, many could do better and there is a need to get the basics right and make more time for training

The top 3 biggest training challenges highlighted in the survey were as follows:

- Scheduling time for training

- Resources / staff to manage training delivery and documentation

- Leadership support for training

Capability frameworks and training needs analysis are currently under-used but could drive improvements if they were more widely and effectively applied. As could the use of technology and tools to help increase training effectiveness (such as through organisation, management, tracking, delivery, communication and evaluation).

However, the top 3 challenges are a powerful reminder that for the situation to improve there needs to be a clear commitment from the business and the senior leadership to provide sufficient time and resources to training and associated activities to ensure the training is effective. Employees need to be competent but also confident, able to do the right thing right, motivated/engaged, and clear on expectations and responsibilities.

Ultimately, improvements will come from driving and sustaining positive behaviours.

How does your training compare?

Join our Training and Development Member Interest Group (MIG). This MIG focuses on the challenges and issues that food and drink businesses deal with to ensure their staff are competent and engaged. The group addresses common industry themes such as high staff turnover, heavy reliance on agency staff, tight budgets, the wide range of training available, and how to ensure that training is effective, enjoyable and impactful. It provides a collaborative environment in which challenges and solutions can be discussed. It is also an ideal forum for networking, horizon scanning, identifying gaps in knowledge and addressing them, as well as keeping up to date with legislation, latest research and other upcoming challenges.

How we can help

We can support your skills and knowledge development as well as continuing professional development (CPD) through our wide range of training courses, on-demand e-learning, seminars and events, white papers and e-books. We also provide tailored training specific to individual business needs – either at our site or yours.

We can provide consultancy and expert advice on best practice in food safety and quality, including reviewing your current training activities and providing recommendations.

Our Culture Excellence program, which we run in partnership with TSI Taylor Shannon International, is a fantastic tool that has been developed specifically for assessing, characterising, strengthening and benchmarking safety and quality culture at manufacturing, retail, food service, distribution and support/corporate sites. It has been designed to support your efforts to drive and sustain positive behaviours.

About Bertrand Emond

Bertrand has a wealth of knowledge, experience and connectivity from working here at Campden BRI since 1988. Bertrand has a Master's in Food Science & Technology (Dijon, France) and a Master's of Business Administration (Bath, UK).

Bertrand is passionate about supporting the industry in the areas of skills, knowledge, training, learning and development, competency and achieving culture excellence through behaviour change. He won the 2020 BRCGS CEO Europe Award recognising his commitment and contribution to food safety and the 2014 Heinz Award for Excellence for Leadership in Collaborative CPD for the Industry (in particular for his role in supporting competency and CPD, promoting the food industry as a career of choice, and providing collaboration between all stakeholders).

Training courses

Interested in our training courses, find out more...

Need support with developing your food safety and quality culture?

We offer a Culture Excellence program and can support you in addressing your findings.