CTemp sales help to continue our work in ensuring safe thermal processes for heat preservation of food and drink

9 December 2022 | Gary Tucker, Fellow at Campden BRI

With our thermal process calculation software now being used on every continent (except Antarctica), we have taken the opportunity to reflect on our history in establishing thermal process guidance. As well as our current offerings in training, validation and troubleshooting, both at Chipping Campden and at our clients’ sites.

CTemp is used to calculate safe thermal process parameters

Our Thermal Processing Group have recently sold their 150th copy of the CTemp programme, which is used by food and drink companies (as well as validation service partners like ourselves) to calculate safe processing times and temperatures for thermally processed products.

It can be used for all types of food and drink products, in a variety of packaging formats, to calculate safe process times for different conditions to those used in validation trials.

Applications include various types of retorts, pasteurisers and ovens used for sterilisation and pasteurisation processes.

Across the wide range of services that we provide across all areas of the food and drink industry, we can provide support to businesses all over the world. The CTemp programme itself is used all around the world by manufacturers of heat preserved foods.

We helped to set thermal processing standards that are still applied to ensure food safety today

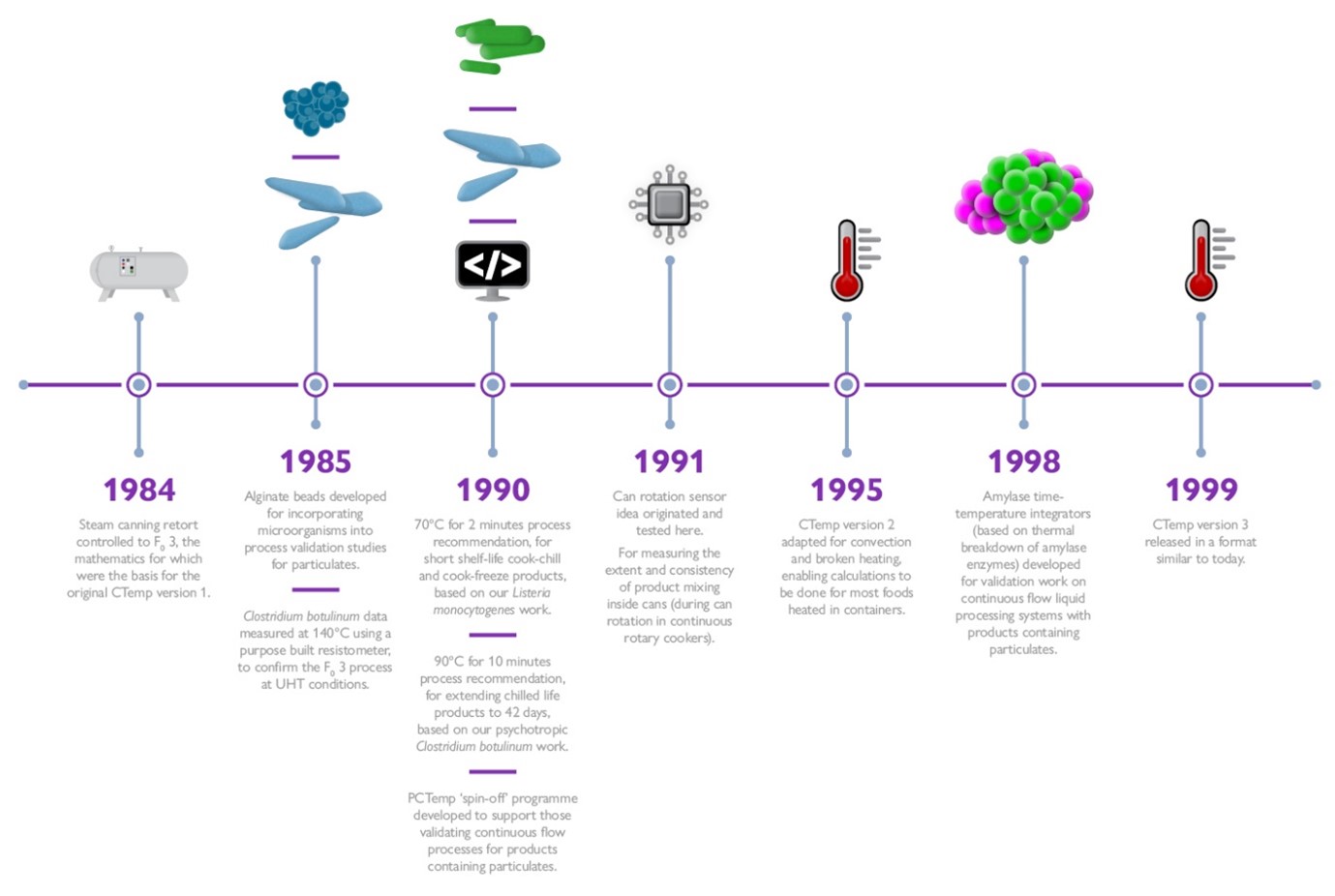

We have almost 100 years of experience dealing with all aspects of heat preserved foods and are behind many advances in the thermal processing field.

Here are some of the highlights:

CTemp has practical, commercial applications for manufacturers of heat preserved food

CTemp uses numerical modelling to solve heat transfer calculations. It models the rate of heat transfer into containers and calculates food internal temperatures during heat processing.

Using temperature probe data from the relevant validation work, it calculates the predicted heating rate of the probe if the conditions (e.g. container size, model organism, starting temperature) were different to those used in the validation trials.

Based on this, CTemp modelling can be used to scope out the feasibility of a change in product (new oven, new packaging) before progressing to validation work. It can also be used as a useful indication, alongside other risk assessment inputs, when establishing whether product affected by unplanned process deviations is safe for sale.

From an efficiency, sustainability and cost perspective, CTemp can also be used to model the retorting process to determine which stages are demanding the most energy.

It can also be used to optimise thermal processes to reduce energy consumption and cost. For scoping optimisation plans, CTemp can be used as an initial feasibility assessment to indicate whether the food safety critical F0 requirement would still be met.

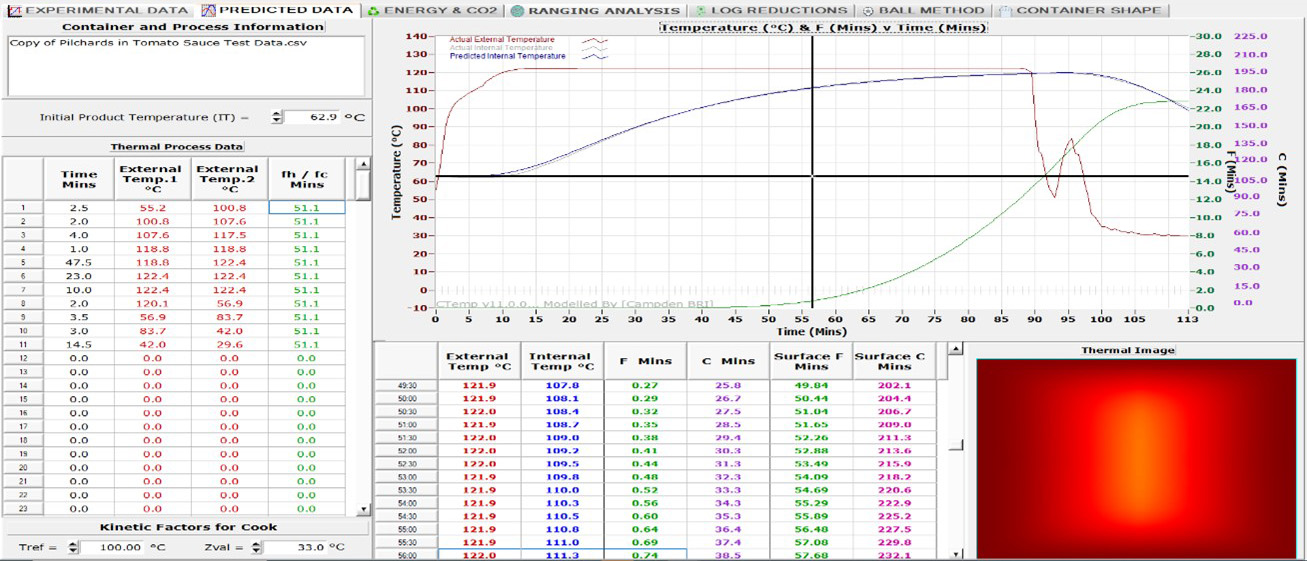

For all application examples, the programme calculates predicted data based on the experimental data (validation data) and on the changes to the validated conditions. An example of predicted data is shown below:

We have clients for which we use CTemp as part of supporting their validation work or process deviation query. We also have clients that have purchased CTemp to use themselves. For clients who use CTemp directly, we can provide guidance on interpreting and applying the data. We provide training packages that are tailored to the applications of the user, to ensure they get the most out of the software.

How can we support your business in relation to thermal processing?

Here is an overview of some of our services in this area:

- A range of thermal processing training courses delivered at Campden BRI and remotely, as well as tailored training delivered at the client’s site

- On Demand E-learning, including on thermal processing

- Validation services from David Whittaker’s Process Innovation Team, for both thermal and non-thermal processes, including;

- Guidance on what factors to consider, conducting the validation itself and performing the calculations, data analysis and interpretations afterwards

- Hands-on support conducting the validation tests at your facility

- Providing specialist equipment to meet the specific validation needs of your process

- Deliver the type of predictive modelling discussed here

- Support manufacturers with third-party process reviews / approvals and other consultancy services

- Provide advice and support for navigating unplanned deviations that have occurred in the thermal processing of your product

- Work with you to confirm that existing processing is sufficient as well as exploring process optimisations and implementing new processes

About David Whittaker

David is a thermal and non-thermal processing specialist and has expertise across many food and beverage sectors.

David also delivers many thermal processing training courses and has a real passion for communication in this area, having spoken at several conferences and seminars on the topic, as well as contributing to Campden BRI guidelines.

How can we help you?

If you’d like to find out more about our thermal process support and validation services, contact our support team to find out how we can help.

Thermal processing training courses

Explore our Thermal processing related courses including; Thermal processing and validation and Thermal processing - continuous flow, live online tutor-led course